Description

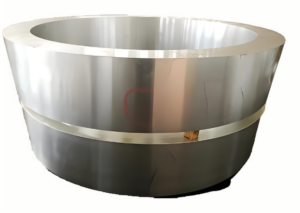

TIPTOP Forging supplies high-quality AISI 4130 forged hollow bars and various forgings. 4130 steel is a chromium-molybdenum alloy steel primarily used in industrial applications. Its excellent strength, toughness, and irreplaceable properties make it the preferred material for structural components across various industries. It is also commonly used in the manufacture of valve bodies, pump bodies, and other critical pressure-bearing components.

2. Forged steel round bars Typical Material Properties

The following are typical chemical composition and mechanical properties for AISI 4130. Our actual products strictly conform to the technical requirements specified in the purchase order.

Chemical Composition

| Chemical Composition | |||||||

| C (%) | Cr (%) | Mn (%) | Mo (%) | Si (%) | P (%) | Ni (%) | S (%) |

| 0.28 – 0.33 | 0.90 – 1.10 | 0.40 – 0.60 | 0.15 – 0.25 | 0.10 – 0.35 | ≤ 0.035 | ≤ 0.25 | ≤ 0.040 |

| Tensile Strength (KSI) | Elongation (%) | Hardness (HRC) |

| 95 – 130 | 20 | 18 – 22 |

3. Our forged bar stock Quality Inspection Process

We implement a strict inspection procedure to ensure reliable performance and specification compliance for every batch of material. Key stages include:

Material & Process Documentation Review: Chemical composition verification per heat number, review of forging reports confirming forging ratio and normalizing heat treatment, and examination of heat treatment records and furnace charts.

Mechanical Property Testing: Hardness, tensile (at room temperature and +180°C), and Charpy impact tests at -29°C are conducted to ensure the material meets performance requirements under actual service conditions.

Non-Destructive Testing & Dimensional Check: 100% ultrasonic testing is performed, along with comprehensive dimensional and visual inspections covering wall thickness measurement, drift testing, and more.

Final Documentation & Pre-shipment Release: Final inspection records are compiled according to EN 10204 3.1 standard, followed by pre-shipment inspection, forming a complete and traceable quality documentation package.

The hollow bar Primary Application Fields

This material is widely used not only in the API 6A compliant oil and gas industry, such as in wellhead equipment, choke valve bodies, and downhole tool assemblies, but also in critical structural components for the aerospace industry, such as aircraft landing gear, engine mounts, and flight control linkages. In defense equipment, it is used in armored vehicle components, weapon mounts, and missile launchers. Furthermore, in the general engineering and heavy machinery industries, this material is frequently used to manufacture important components such as hydraulic cylinders, high-performance shafts, gear blanks, and large connecting rods.

Why Choose Us TIPTOP Forging

Our 4130 alloy steel forgings and bars hold multiple authoritative certifications, such as ISO, ensuring full traceability and consistent quality reliability.

We support rapid response and flexible customization, processing to meet your size and specification requirements and facilitating efficient project progress with short delivery cycles.

Furthermore, our hollow bar specifications offers a complete range of specifications at excellent cost-effectiveness. Our products feature superior mechanical properties, high tensile strength, and excellent surface treatment, along with rust protection, significantly enhancing durability and service life to meet the long-term needs of various industries.

Reviews

There are no reviews yet.