Description

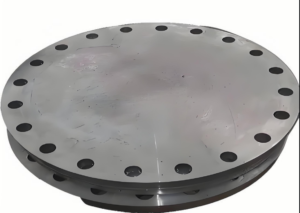

Product Overview

Drill Bit Forging is the necessary intermediate step in manufacturing high-performance drilling bits used in oil & gas, mining, geothermal, and development drilling. By the use of precision forging techniques, we supply cast blanks with ideal grain flow, excessive structural integrity, and awesome longevity — all tailor-made to live to tell the tale the cruelest drilling environments.

As a expert forging producer in China, we furnish customized and general Drill Bit Forgings to your specifications, making sure dependable quality, aggressive pricing, and international delivery.

What is Drill Bit Forging?

Drill Bit Forging is a procedure of shaping heated alloy steel or carbon metal preforms below excessive stress to produce near-net-shape blanks for drilling bit manufacturing. Compared with forged or machined-from-billet options, cast drill bits offer:

✅ Dense, subtle grain shape for most desirable toughness

✅ Reduced threat of cracking or failure underneath severe loads

✅ Greater have an effect on resistance, necessary for tough rock drilling

✅ Excellent machinability for ending operations

These solid blanks serve as the beginning factor for PDC bits, tricone bits, drag bits, and customized reducing tools.

Advantages of Our Drill Bit Forgings

✅ Premium Alloy Steel & Carbon Steel Options

Materials chosen to meet API/ISO standards

Heat-treated for regular mechanical properties

✅ Superior Mechanical Strength

Uniform grain float improves fatigue life

High affect resistance for shock loads

✅ Custom Sizes and Shapes Available

Near-net shapes limit machining time and waste

Fully tailor-made dimensions to healthy your tooling and designs

✅ Excellent Quality Control

Full traceability with cloth certificates

Ultrasonic testing, hardness, and dimensional inspection available

✅ Competitive Pricing & Global Delivery

Direct-from-factory pricing

Secure packaging and global shipping

Typical Applications

PDC (Polycrystalline Diamond Compact) Drill Bits

Tricone Roller Cone Bits

Drag Bits and Custom Cutting Tools

Mining and Quarry Drilling Tools

Oil & Gas Exploration Bits

Geothermal Drilling Equipment

Material Options

✅ Carbon Steels: AISI 1045, AISI 1050, AISI 4140

✅ Alloy Steels: 4130, 4340, 8620

✅ Custom Grades Available on Request

Available Heat Treatments

✅ Normalized

✅ Quenched and Tempered

✅ Annealed

✅ Customized Heat-Treatment Profiles

Typical Product Dimensions and Specs

| Specification | Range/Options |

| Outside Diameter (OD) | 50 mm – 500 mm (customizable) |

| Length / Height | 50 mm – 500 mm (customizable) |

| Weight Range | 2 kg – 500 kg per piece |

| Material Grades | Carbon steel, Alloy steel, as specified |

| Heat Treatment | Normalized, Q&T, Annealed |

| Tolerances | As per drawing / industry standards |

| Surface Finish | As forged / Machined / Blasted |

| Testing Options | UT, MPI, Hardness, Mechanical Tests |

Quality Assurance

✅ Fully licensed uncooked substances with MTC (EN 10204 3.1 / 3.2 available)

✅ In-process inspections

✅ Dimensional reviews as required

✅ Ultrasonic Testing (UT) for inner soundness

✅ Magnetic Particle Inspection (MPI) for floor cracks

Why Choose Us for Drill Bit Forgings?

✅ Proven Forging Expertise

Over 20 years of ride imparting oil & gas, mining, and heavy enterprise clients worldwide.

✅ Custom Engineering Support

We can evaluation your drawings and assist optimize shapes for forging effectivity and machining savings.

✅ Flexible Production

From small prototyping batches to large-scale manufacturing orders.

✅ Global Export Ready

ISPM-15 licensed wood packaging, clear labeling, and full export documentation support.

Get a Quote for Drill Bit Forgings

Your drilling bit’s overall performance starts offevolved with the proper forging. Investing in top notch Drill Bit Forgings ensures safer, greater reliable, and good value drilling operations.

👉 Contact us these days to talk about your requirements, request a certain quote, or get technical recommendation on fabric determination and forging design

Reviews

There are no reviews yet.