Description

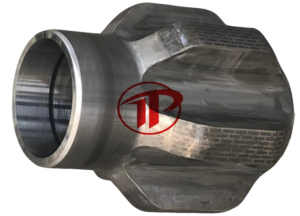

Hollow shaft is a mechanical transmission component with a central through-hole machined along its axis. Its external surface typically features a stepped cylindrical design and is equipped with external keyways, while the internal bore can be machined with internal keyways to accommodate various transmission requirements. Compared to a solid shaft, this structure offers superior torsional stiffness. When the outer diameter and cross-sectional area are equal, the hollow shaft optimizes material distribution, allowing the outer layer of material to provide enhanced resistance to torque.

Functions of Forged Alloy Steel Hollow Shafts

Our forged alloy steel hollow shafts serve three main functions: firstly, the hollow shaft acts as a power transmission component, capable of transmitting significant torque and rotational power; secondly, it allows for weight reduction and optimization, significantly reducing the overall system weight without significantly compromising torsional rigidity; and thirdly, the hollow shaft can serve as a multi-functional conduit, with the central bore acting as a path for coolant circulation, lubrication oil, hydraulic control lines, or electrical cables.

Applications of Forged Alloy Steel Hollow Shafts

Our hollow shafts have a wide range of applications. In the wind power industry, hollow shafts can be used as the main shafts of wind turbines; in the marine power field, they can be used as intermediate shafts and tail shafts in propulsion systems; in the energy and power sector, they can be used as rotor shafts for gas turbines and steam turbines; and in other heavy machinery, hollow shafts can also be used as transmission shafts for rolling mills, slewing shafts for large excavators, and so on.

Forged Alloy Steel Hollow Shaft Manufacturing Advantages

We specialize in forged alloy steel hollow shafts designed to bridge the gap between high power demands and weight efficiency.

Optimized Integrity

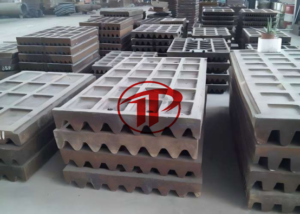

Forging densifies the steel’s structure, providing a level of fatigue resistance that cast or machined bars simply can’t match. You get a lighter shaft that actually performs better under high-torque rotation.

Advanced Shaping

We forge complex features-like internal/external splines and multi-diameter steps-directly into the component. This “near-net” approach means less wasted material and faster assembly times for your project.

Specialized Metallurgy

We don’t believe in one-size-fits-all. From standard 35CrMo for robust daily use to elite grades like 3oNiCrMoV12 for ultra-high-toughness applications, our material lab ensures the alloy fits the stress of your application.

Q&A – Forged Alloy Steel Hollow Shaft

What materials can be used for forged alloy steel hollow shafts?

A:General/Medium-to-high strength grade: AISI 4140 or 42CrMo4; High-strength grade: AISI 4340 / 34CrNiMo6; High-temperature/high-pressure special grade: 30CrNiMo8 / 30NiCrMoV12 or other customized materials.

How can we guarantee the quality of forged alloy steel hollow shafts?

A:We can perform ultrasonic testing (UT) or magnetic particle testing (MT) to ensure there are no internal cracks or inclusions, guaranteeing safe operation and ensuring that there are no micro-cracks on the surface of stress concentration areas such as the shaft shoulder.

Reviews

There are no reviews yet.