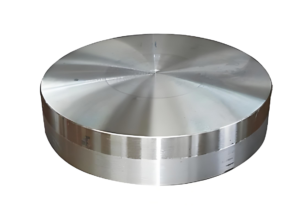

Description

Why Forged Shafts Are the Best Choice for Crankshaft and Driveshaft Applications

Forged crankshafts and power shafts are engineered to supply fantastic energy and sturdiness in the most traumatic mechanical systems. Whether powering industrial machines, heavy vehicles, or marine propulsion systems, forged shafts furnish optimum fatigue resistance and structural reliability in contrast to solid or machined alternatives.

Key Benefits at a Glance:

✅ Exceptional fatigue life under cyclic loading

✅ Improved grain structure for higher torsional strength

✅ No porosity or internal voids – high integrity metal

✅ Ideal for high-RPM, high-load, and long-service environments

Crankshaft and Drive Shaft Applications

Our forged shafts are widely used across industries where mechanical failure is not an option:

Application Common Shaft Types

Automotive Crankshafts, transmission shafts

Oil & Gas Mud pump drive shafts, compressor shafts

Marine Propeller shafts, intermediate shafts

Power Generation Rotor shafts, turbine shafts

Heavy Equipment Axle shafts, PTO shafts

Materials We Offer for Forged Shafts

We provide a full range of alloy and carbon steel grades suitable for forging crankshafts and drive shafts:

Grade Specification Key Features

AISI 4140 ASTM A29 / EN 10083 High strength, wear resistance

AISI 4340 ASTM A322 Excellent toughness & fatigue resistance

42CrMo4 EN 10250 Widely used in Europe for shaft forging

17CrNiMo6 EN 10084 Case hardening steel with high core strength

F22 / 2CrMo ASTM A182 Suitable for high-temp and high-pressure systems

🔧 All materials can be supplied with Q&T (quench and temper) heat treatment and full mechanical property certifications.

Technical Capabilities & Supply Range

We can deliver forged shafts in a wide range of sizes and shapes:

Diameter: 100 mm – 1,000 mm

Length: Up to 10 meters

Shapes: Round, stepped, splined, or flanged

Finish: As-forged, rough machined, or fully machined (±0.01 mm tolerance)

We also provide:

Ultrasonic Testing (UT Level 2/3 per ASTM A388)

Magnetic Particle Testing (MT)

Hardness, tensile, and impact testing

Surface treatment (shot blasting, anti-corrosion coating)

Forged vs Cast Shafts – Why Forged Wins Every Time

Feature Forged Shaft Cast Shaft

Grain Flow Aligned with shaft geometry Random and discontinuous

Porosity None (dense structure) Risk of internal voids

Fatigue Life Excellent Poor to moderate

Strength-to-Weight Higher Lower

Machinability Better control after heat treatment Often needs post-processing

Certifications & Industry Standards

We comply with major global quality and material standards:

✅ ISO 9001, API 6A, AS9100

✅ EN 10204 3.1 / 3.2 Mill Test Certificates

✅ ABS / DNV / BV marine shaft certification

✅ NDT reports available upon request

Request a Quote or Custom Shaft Solution

Looking for forged crankshafts or drive shafts for your next project?

📩 Contact us with your specifications or technical drawings. Our engineering team can help you select the best material, forging process, and finish to meet your performance and budget goals.

Reviews

There are no reviews yet.