Description

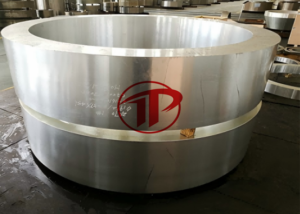

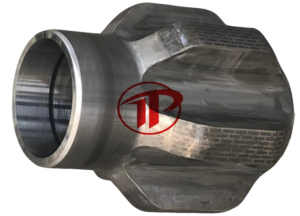

Product Overview

Our cast crusher hammers are precision-engineered elements designed for hard crushing purposes in mining, aggregate, cement, and strength era industries. Manufactured thru superior forging processes, these hammers supply magnificent strength, durability, and put on resistance — making them the perfect desire for breaking substances such as cobblestone, coal gangue, and limestone.

Forging transforms great metal billets into dense, fine-grained hammer heads with uniform mechanical properties. This most suitable microstructure ensures incredible have an effect on resistance, decreased breakage risk, and longer provider existence below the most disturbing crushing conditions.

Key Features & Benefits

✅ Exceptional Impact Resistance

Forged from premium-grade teach wheel hub metal (65Mn) to stand up to repeated high-energy impacts.

✅ Superior Wear Resistance

Quenching and warmness therapy create a hardened working surface, handing over tremendous put on lifestyles even in abrasive environments.

✅ High Toughness & Low Breakage Risk

Forging refines grain go with the flow and eliminates inside defects frequent in castings, decreasing the danger of catastrophic failure.

✅ Precision Shape & Consistency

Controlled forging processes achieve tight dimensional tolerances for perfect fit and balanced operation.

Typical Applications

Cobblestone crushing

Coal gangue processing

Limestone breaking

Cement plant crushers

Mining and aggregate crushing equipment

Materials Available

We offer forged crusher hammers in a range of high-performance steel grades to suit different wear and impact requirements:

| Material | Composition Highlight | Application Benefit |

| Mn13 | High-manganese steel | Excellent work-hardening & impact strength |

| Mn13Cr2 | Manganese-chromium alloy | Improved hardness & wear resistance |

| Mn18Cr2 | High-manganese with elevated chromium | Maximum wear life for extreme conditions |

Forging Process Advantages

Unlike cast crusher hammers, forged hammers undergo repeated high-pressure hammering that refines the metal’s grain structure, improves toughness, and eliminates internal voids or porosity. This results in:

Dense, uniform microstructure

Consistent hardness after heat treatment

Improved fatigue resistance

Superior overall reliability in service

Technical Specifications Table

| Parameter | Typical Range or Feature |

| Weight | 5 kg – 200 kg (custom available) |

| Dimensions | As per customer drawing / standard models |

| Hardness | Up to HRC 55–60 (depending on material and treatment) |

| Heat Treatment | Quenching & tempering, work-hardening compatible |

| Surface Finish | Machined contact surfaces for precise fit |

| Customization | Logo marking, machining holes/slots, balancing |

Why Choose Our Forged Crusher Hammers?

- Advanced forging lines for large-scale production

- Strict quality control with ultrasonic testing

- In-house heat treatment for tailored hardness

- Engineering support for custom designs

- Competitive pricing with global shipping

Contact Us

Looking for forged crusher hammers with unbeatable durability and performance? We’re here to help.

👉 Contact our team today to discuss your requirements, request a quote, or learn more about our forging capabilities for crushing equipment components.

Reviews

There are no reviews yet.