Description

High-Strength Custom Forging with Thermal Fit and Easy Disassembly Design

Product Description

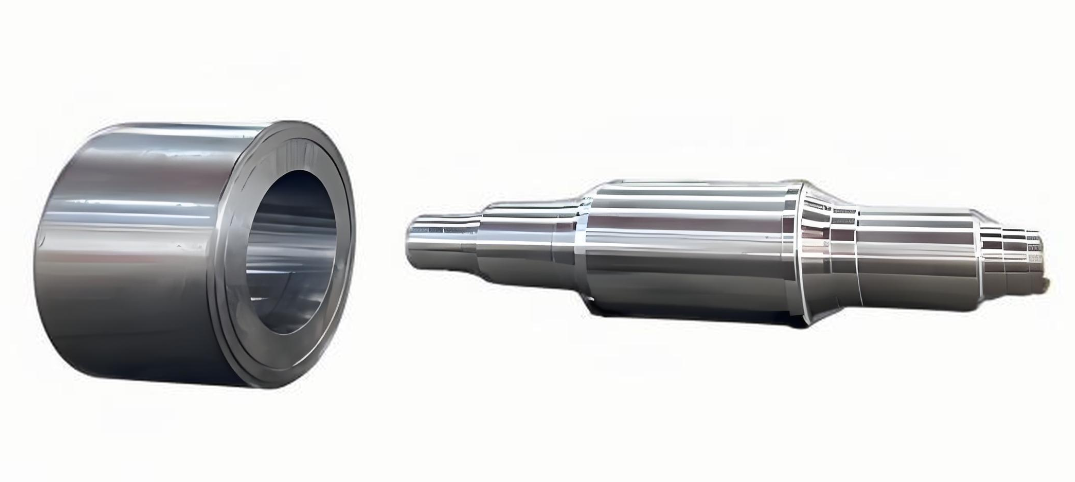

The Forged Roller Shaft and Sleeve Assembly is specifically engineered for rolling mill systems and other heavy-duty industrial machinery requiring superior strength and precision. Both the roller shaft and sleeve are manufactured through high-quality forging processes to ensure excellent mechanical properties, wear resistance, and dimensional integrity under high loads and harsh working environments.

To improve operational efficiency, the system utilizes a medium-frequency induction heating and internal water cooling technique. This dual thermal mechanism rapidly creates a temperature-induced gap between the roller sleeve and the shaft, significantly increasing disassembly speed and minimizing mechanical stress on components.

During assembly, a motor-driven expansion device with a specially designed clamping structure allows precise control of the sleeve’s positioning. This enables accurate gap adjustment, reduces installation errors, and enhances overall system stability and flexibility.

Key Features

Precision Forging: Both components are forged from premium alloy steel for enhanced strength, durability, and fatigue resistance.

Fast Maintenance: Thermal expansion and cooling system allows for quick, safe disassembly without damaging parts.

Adjustable Assembly: Motor-driven expansion ensures precise gap fitting for optimal sleeve-to-shaft contact.

Reduced Downtime: Easy maintenance and simplified disassembly streamline operational workflows.

Customizable Options: Material grade, dimensions, and surface treatments can be customized to meet specific operational requirements.

Typical Applications

Rolling mills (hot/cold strip mills)

Steel and aluminum processing equipment

Cement and mining industry machinery

Custom forging machines and shaft systems

Heavy mechanical transmission equipment

Technical Parameters (Available Upon Request)

Forging Method: Open die or closed die

Materials: 42CrMo, 4140, 35CrMo, or customer-specified alloy steel

Surface Finish: Machined, heat treated, or coated

Dimensional Range: Custom diameters and lengths available

Standards: API, ASTM, ISO, GB or tailored specs

Why Choose Our Forged Roller Shaft & Sleeve?

With decades of expertise in large industrial forgings, we provide precision-engineered components that meet the most demanding working conditions. From material selection to thermal processing and final machining, we ensure reliability, performance, and longevity at every stage.

Reviews

There are no reviews yet.