Description

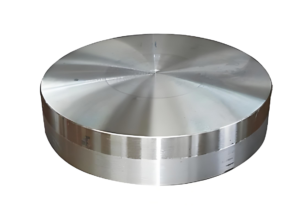

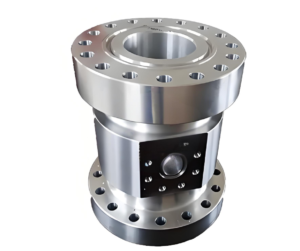

Fracturing Head Forging (also recognized as Frac Head Forging) is a critical, high-pressure thing used in hydraulic fracturing operations to safely and efficaciously deliver frac fluid into the wellhead. Our solid frac heads are precision-engineered to face up to excessive pressures, abrasive fluids, and disturbing area conditions.

Product Features and Benefits

✅ High-Strength Forging Process

Our Fracturing Heads are produced the usage of superior open-die and closed-die forging methods, making sure top of the line mechanical homes and regular grain flow. This promises unmatched power and fatigue resistance, even beneath cyclic high-pressure fracturing jobs.

✅ Pressure Ratings up to 15,000 psi

Engineered to meet or exceed API 6A specifications, our forged frac heads cope with the intense pressures of modern-day stimulation operations.

✅ Excellent Corrosion Resistance

Made from top rate alloy steels with optionally available bitter provider substances and coatings to face up to harsh chemical substances and corrosive frac fluids.

✅ Custom Configurations Available

We manufacture single or multi-port designs, threaded or flanged outlets, and bespoke dimensions to healthy your fracturing manifold requirements.

✅ Heat Treatment for Toughness

Normalized, quenched and tempered for multiplied toughness, have an effect on resistance, and provider life.

Typical Applications

Hydraulic fracturing (fracking) operations

Shale gasoline and tight oil nicely stimulation

High-pressure pumping systems

Wellhead frac bushes and manifolds

Technical Specifications (Example Table)

| Parameter | Typical Value / Options |

| Pressure Rating | 5,000 – 15,000 psi |

| Size | 2-1/16″ to 7-1/16″ flange sizes |

| Material | AISI 4130, 4140, 8630, F22, stainless steels |

| Heat Treatment | Normalized, quenched and tempered |

| Connection Types | API 6A flanges, threaded outlets |

| Testing & Certification | UT, MPI, Hydrostatic test, API 6A/ISO9001 |

Why Choose Our Forged Frac Heads?

✅ Fully traceable cast metal from licensed mills

✅ API 6A-compliant plan and manufacturing

✅ High-pressure sealing integrity for safer operations

✅ Custom sizes and configurations on request

✅ Global transport with invulnerable packaging and documentation

Available Custom Options

Body Material: Sour-service certified alloys, carbon steels

Outlet Ports: Flanged, threaded, studded, or customized adapters

Surface Coating: Zinc plating, phosphating, Xylan, paint

Heat Treatment: Customized to carrier conditions

Testing: Full NDT, stress test, fabric certificates

Contact Us

Need dependable Fracturing Head Forging options for your oilfield projects?

Reviews

There are no reviews yet.