Description

1. What Constitutes a Heavy-duty

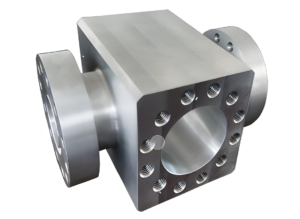

For example, a heavy-duty forged flange is a high-strength pressure component that is used for the connection of ROi, valves, pumps, pressure vessels, and the rest of the core industrial equipment. In contrast to normal ones, heavy-duty forged flanges are definitely characterized for tough conditions such as high temperatures, vibrations, alternate loads, and corrosive media.

By forging a flange the metal’s internal grain direction becomes continuous and dense, thus the mechanical properties are much better than those of cast or welded ones. Hence, forged steel flanges possess great sealing stability and structural integrity over a long period of time even in demanding conditions.

2. Reasons why Heavy-duty

The heavy-duty steel forged flanges are the main pressure-bearing connectors that guarantee the safety of processes which are of high-risk and high-value. Their usage covers the most challenging sectors of the world:

Oil & Gas Industry

There is no compromise on the heavy-duty forged flange connections that are necessary for high-pressure pipelines, refinery units, FPSO systems, and subsea infrastructures. They enhance sealing stability when extreme internal pressure and complicated marine environments are involved, thus ensuring the safety of the equipment and the whole production system.

Chemical & Petrochemical Sector

In these, forging carbon steel flanges are the hardest and most airtight ones that can withstand chemical erosion and resist the given environment. Their reliable construction guarantees permanent safety in the presence of acids, alkalis, and high-temperature media of the process.

Power Generation & Nuclear Applications

Supercritical and ultra-supercritical power plants rely on carbon steel forged flanges for high-pressure steam pipelines. In nuclear facilities, heavy-duty forged flanges are manufactured to nuclear safety standards and used for critical equipment such as reactor pressure vessel nozzles and main pump connections where zero failure is permitted.

Marine Engineering & Offshore Equipment

Deep-sea drilling platforms, ship propulsion systems, and marine pipelines use forged steel flanges capable of withstanding cyclic dynamic loads, saltwater corrosion, and long periods of high-stress operation.

Aerospace & Heavy Machinery

In aerospace launch systems and large mechanical equipment, heavy-duty flanges help maintain structural strength while meeting strict weight, fatigue, and performance requirements.

3. Core Advantages of Our Heavy-duty Forged Flanges

Exceptional Structural Integrity

The forging process forms continuous metal flow lines, eliminating porosity, shrinkage, and segregation—defects that often occur in cast components. This gives heavy-duty forged flanges superior fatigue resistance and a higher safety factor under extreme pressure or vibration.

Large-Diameter & Special-Shape Customization

With advanced ring-rolling equipment and controlled heat treatment technology, we specialize in oversized, thick-wall, or irregular forged flange geometries. This includes custom ultra-large forged flanges for high-energy pipelines and heavy mechanical systems.

High Reliability Under Harsh Conditions

Using refined metallurgical processes, our steel forged flanges achieve high density, strength, and uniformity—ensuring stable performance under static loads, impact loads, or high-frequency pressure cycles.

Material & Cost Efficiency

Near-net-shape forming during forging significantly improves material utilization. This not only reduces wastage but also minimizes machining time, lowering overall production cost compared to conventional forging routes.

4.Material Options for Heavy-duty Forged Flanges

We are offering our heavy-duty flanges in a wide variety of materials depending on the project requirements:

- Forged carbon steel flanges

- Carbon steel forged flanges (for normal pressure lines)

- Steel forged flanges (for high-pressure and high-temperature service)

- Low-temperature steel LNG pipelines

- Corrosion resistant stainless steel with plastic lining

- Comfortable high-alloy and nickel-based flanges for extreme applications

Every single material is chosen in order to satisfy the determined pressure, temperature, corrosion, and mechanical performance requirements.

5. Custom Forging and Engineering Support

We offer you completely customized forging solutions – starting from the selection of the appropriate material grade up to the designing of the most suitable flange structure for high-pressure sealing performance. The experts from our forging department will guarantee that you will get your standard pipeline connection or mission-critical pressure component made by forging, which will be strong, reliable, and have a long lifespan.

Conclusion

Heavy-duty forged flanges are the core components that have enabled the rise of energy, chemical, marine, and power industries worldwide. We achieve it by advanced forging technology, rigorous quality control, and profound metallurgical knowledge.

Reviews

There are no reviews yet.