Description

Gear Shaft Description

TIPTOP Forging understands that gears are an indispensable driving force for rotary motion across various industries. We specialize in manufacturing high-quality forged gear shafts that meet customer satisfaction. Our gear shafts are used in a wide range of applications, from automotive and power generation to railways, marine vessels, steel mills, and heavy industrial plants.We have a professional team that can meticulously research and manufacture products according to customer-provided drawings.

Typical Materials for Gear Shafts

TIPTOP strictly select suitable materials based on the performance of gear shafts. Based on their differennt application , materials used for free forging large gear shafts typically include the following categories:

Alloy steel (mainly used for high-strength applications)

20CrMnTi: Gear shafts in automobiles and heavy machinery.

42CrMo : It is usually an ideal choice for high-stress components such as heavy-duty gears and drive shafts.

40CrNiMo : Suitable for the most demanding application environments.

“High strength/Engineering steel” :

34CrNiMo6 : Suitable for large gear shafts that require high durability even under extreme loads.

25CrMo4 : It is often used in large transmission shafts and other high-strength structural components.

Stainless steel (for corrosive environments)

Austenitic stainless steel (304/316) : Suitable for environments that require high corrosion resistance, such as in the chemical or Marine engineering fields.

“Tool steel” (for special working conditions) :

H13 (Hot Work die steel) : Mainly used for making gear shafts that operate in high-temperature environments.

Other special alloys (for extreme performance requirements)

Titanium alloy : Used in aerospace and defense fields.

Aluminum alloy : Mainly used in industries sensitive to weight.

Gear Shaft Manufacturing Process

Forging –Normalizing –Rough machining –UT test –heat treatment (test hardness)–Semi-finishing machining– Gear Teeth Hobbing –Surface Hardening –teeth grinding –checking and packing

Applications of Gear Shafts and Gear Pinion Shafts

Forged gear shafts are primarily used in heavy-duty, high-speed, and critical equipment that demands extremely high strength, reliability, and durability.

The following are its main application areas:

Energy and Power

Wind Power: High-speed shafts and low-speed main shafts in wind turbine gearboxes.

Thermal/Hydroelectric Power: Transmission shafts and turbine speed control system gear shafts in generator sets.

Nuclear Power: Critical shaft components in auxiliary transmission systems, requiring extremely high reliability and material purity.

Transportation

Ships: Main propulsion systems and deck machinery (such as winches) transmission gear shafts in large ships, requiring corrosion resistance and the ability to withstand enormous loads.

Rail Transit: Traction gear shafts in locomotive and high-speed rail transmission systems, requiring extremely high fatigue strength and safety.

Heavy Vehicles: Core gear shafts in the gearboxes and drive axles of mining trucks and construction machinery.

Resource Extraction and Metallurgy

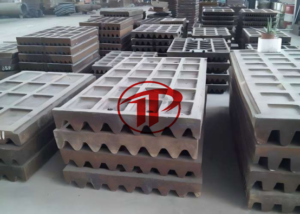

Mining Machinery: Core transmission shafts in ball mills, crushers, and large hoists, operating in harsh environments and under extremely heavy loads.

Metallurgical Rolling: Gear seats and herringbone gear shafts of large rolling mills, withstanding huge impact torque in high-temperature, high-dust environments.

Industrial Machine Tools and Heavy Machinery

Gear Processing Machine Tools: As the heart of the machine tool’s transmission system, requiring extremely high precision and rigidity.

Plastics/Rubber Machinery: Drive gear shafts of large mixers and extruders.

Building Materials Equipment: Drive gear shafts of cement rotary kilns and large grinding mills.

Why Choose TIPTOP Gear Shaft Manufacturers

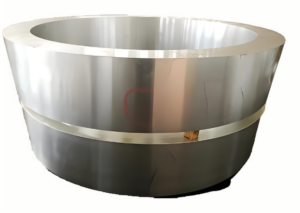

The core strength of TIPTOP lies in its ability to produce large-sized, high-quality forged gear shaft blanks, which are specifically designed for the subsequent manufacturing of high-performance finished gears.

Choosing TIPTOP forging means choosing a reliable partner that not only offers the robustness and durability brought by the forging process but also meets the precision performance requirements of demanding applications.

Reviews

There are no reviews yet.