Description

A stainless steel bar is an essential raw material used across mechanical engineering, petrochemical equipment, marine hardware, precision machining, and structural fabrication. Its combination of corrosion resistance, strength, and formability makes it one of the most dependable metal bar products in modern manufacturing.

At TIP TOP Forging, we supply forged and machined stainless steel bars in a complete range of grades and sizes. Whether you need 304 stainless steel round bar, 316 stainless steel round bar, or alloy options like 4130 steel round bar, we offer stable quality and customizable solutions tailored to industrial requirements.

Stainless Steel Bar Variants and Industrial Grades

TIP TOP provides multiple stainless steel bar types to meet different performance needs:

304 Stainless Steel Bar for General Engineering

304 stainless steel bar remains the most widely used material due to its balance of corrosion resistance and mechanical strength.

Typical uses include brackets, shafts, fittings, and general mechanical components.

316 Stainless Steel Bar for Marine and Chemical Service

316 stainless steel bar offers stronger resistance to chlorides and aggressive environments, making it suitable for:

Marine hardware

Pump shafts

Chemical processing equipment

Valve components

Stainless Steel Round Bar in Standard Sizes

We supply round bars in common machining sizes, including 1 inch steel round bar, which is frequently used for fittings, shafts, and CNC machining tasks.

Alloy Steel Round Bar Options

For applications requiring higher strength and toughness, TIP TOP provides alloy options such as 4130 steel round bar.

This grade is commonly used in:

Oilfield tools

Aerospace structures

High-load mechanical parts

Manufacturing Process for Stainless Steel Bar Production

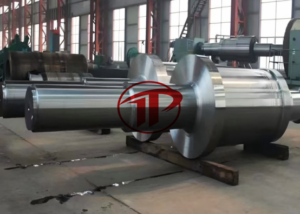

Unlike stock-only distributors, TIP TOP specializes in forged stainless steel bar production.

Our manufacturing capabilities ensure higher density, improved uniformity, and enhanced mechanical performance.

Our stainless steel bar manufacturing steps include:

- Open-die or closed-die forging for improved internal structure

- Heat treatment to achieve stable hardness and strength

- Rough machining & precision turning to control tolerances

- Peeling, polishing & grinding for surface refinement

- Cut-to-length processing for bar stock steel orders

- Dimensional straightness control for CNC machining suitability

This ensures that every stainless steel bar meets strict dimensional and quality expectations.

Stainless Steel Bar Performance Characteristics

TIP TOP stainless steel bars are engineered to deliver dependable performance in various operating environments.

Key characteristics include:

- Excellent corrosion resistance in wet, marine, and chemical surroundings

- High tensile strength for structural loads

- Good machinability for precision shaping

- Resistance to heat and oxidation

- Suitable for welding and fabrication

These properties make our bar stainless steel ideal for machining shops, OEM manufacturers, and industrial equipment suppliers.

Applications of Stainless Steel Bar in Different Industries

Depending on the grade and size, stainless steel bar is widely applied in:

- Mechanical shafts, pump shafts, and spindle components

- Marine fasteners and shipbuilding hardware

- Food and beverage processing equipment

- Petrochemical plants and pipeline supports

- Machined parts such as bushings, fittings, rings, and brackets

- Precision-engineered components for energy and mining equipment

Whether you need mass production bar stock steel or custom-machined stainless steel components, TIP TOP supports flexible batch sizes and consistent supply.

Why Choose TIP TOP Forging as Your Stainless Steel Bar Supplier

As a professional forging and machining manufacturer, TIP TOP offers advantages that standard stockists cannot match:

✓ Integrated forging + machining production

✓ High-density forged stainless steel bar with superior mechanical strength

✓ Full-grade supply: 304, 316, duplex, martensitic, and alloy steels

✓ Custom production of non-standard lengths and diameters

✓ Professional QC including chemical, mechanical, and ultrasonic testing

✓ Global shipment with stable delivery schedules

We support OEM projects, engineering contractors, and industrial equipment manufacturers requiring reliable long-term stainless steel bar supply.

Custom Stainless Steel Bar Solutions for Industrial Buyers

TIP TOP accepts custom requirements for:

- Oversized or heavy forged stainless steel bars

- Precision machined bars for shaft manufacturing

- Stainless steel round bar with special tolerances

- Non-standard alloys and duplex stainless steels

- High-strength forging for critical applications

Our engineering team works directly with customers to ensure the stainless steel bar fits exact technical requirements.

Conclusion: Reliable Stainless Steel Bar Supply from TIP TOP Forging

Whether you are sourcing 304 stainless steel round bar, 316 stainless steel bar, alloy grades, or precision-machined stainless steel bars, TIP TOP delivers durable quality and dependable supply.

Our forging expertise, strict inspection procedures, and flexible customization capabilities make us a trusted stainless steel bar supplier for global industries.

Reviews

There are no reviews yet.