Description

Introduction

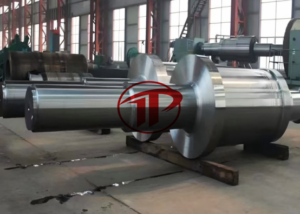

Hot Mould Forging Blocks are precision-forged metallic blocks used in die and mould making for industries the area durability, toughness, and precision are critical. Through a high-temperature forging process, these blocks obtain extra suited grain structure, making them ideal for heavy-duty tooling functions in automotive, aerospace, construction, and strength sectors.

Why Choose Our Hot Mould Forging Blocks?

✅ Superior Strength and Toughness – Refined grain structure guarantees immoderate resistance to wear, fatigue, and thermal cracking

✅ Consistent Quality – Reduced internal voids and inclusions for longer service life and higher reliability

✅ Excellent Machinability – Enables precision machining for tight tolerances and problematic die shapes

✅ Versatility in Materials – Choice of pinnacle type system steels and alloys, alongside with H13, P20, 4140, and personalized grades

✅ Tailored Solutions – Custom sizes, shapes, and specs reachable upon request

Typical Applications

Die & Mould Making – Forging dies, plastic injection moulds, and precision gadget blocks

Automotive – Engine die blocks, gear forging dies, and tooling assemblies

Aerospace – High-strength dies for vital aerospace component production

Construction & Heavy Equipment – Forging dies for large-scale tools parts

Energy – Dies and tooling for oil & gas and electrical energy technological know-how equipment

Material Options

Tool Steels: H13, P20, 1.2344

Alloy Steels: 4140, 4340, F22, F91

Stainless Steels: 410, 420, 17-4PH

Other Alloys: Inconel 625, Incoloy 825 (upon request)

All Hot Mould Forging Blocks adhere to world necessities such as ASTM, ASME, EN, ISO, and API.

Why Choose Us?

✅ Modern Forging Capabilities – State-of-the-art equipment for precision, quality, and scalability

✅ Material Traceability – UT inspection, mechanical testing, and certifications accessible for every and each and every block

✅ Customization Expertise – Tailor blocks to your unique dimensions, specifications, and general overall performance requirements

✅ Global Export Service – Reliable packaging and nicely timed transport for global projects

✅ Cost-Effective Solutions – Premium wonderful delivered at aggressive pricing

Technical Parameters

| Parameter | Specification |

| Material Options | H13, P20, 4140, 4340, F22, F91, 410, 420, 17-4PH, Inconel, Incoloy |

| Forging Method | Open Die / Closed Die Forging |

| Diameter Range | 100mm–2500mm |

| Length Range | 100mm–6000mm |

| Weight Range | 100kg–30,000kg |

| Heat Treatment | Normalizing, Quenching, Tempering |

| Surface Finish | As Forged, Rough Machined, Final Finish |

| Compliance Standards | ASTM, ASME, EN, ISO, API |

| Testing Methods | UT, MPI, Hardness Testing, Material Composition Testing |

| Certifications | EN10204 3.1 / 3.2, NDT Reports available upon request |

Reviews

There are no reviews yet.