Description

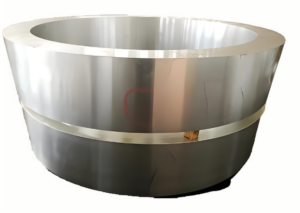

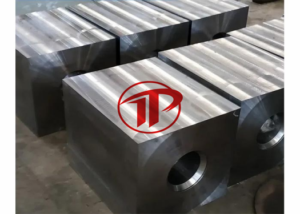

Large Ring Gear and Gear Ring Forgings for Heavy Rotary Equipment

Girth gear forgings, also known as large ring gears or gear ring forgings, are core transmission components of large rotary equipment (such as rotary kilns, ball mills, and dryers). As a type of heavy-duty ring gear, the girth gear serves as the “heart” of the transmission system. Its structural integrity, material quality, and machining accuracy directly determine the operational stability, safety, and service life of the entire production line.

In practical industrial applications, large ring gears usually operate under low speed, high torque, continuous load, and harsh working environments. Choosing TIPTOP Forging as your large ring gear manufacturer means choosing a professional team with long-term experience in ring gear material control, forging integrity, and dimensional stability, especially in the manufacturing of ultra-large diameter gear rings for heavy equipment.

Ring Gear Material Selection and Performance for Heavy-Duty Gear Ring

High-Strength Materials Used in Large Ring Gear Forgings

The performance of a ring gear largely depends on the selection and metallurgical quality of the ring gear material. For heavy-duty gear ring applications, we mainly use high-quality medium-carbon alloy steel or high-strength alloy structural steel.

Common material grades include domestic standards such as 42CrMo and 35CrMo, as well as international equivalents like AISI 4340 and 34CrNiMo6. All materials are produced through controlled smelting routes (electric furnace smelting + ladle refining) to ensure high internal cleanliness, stable chemical composition, and excellent hardenability—critical factors for large ring gear forgings.

To meet the extreme operating conditions of large ring gears under heavy load and long-term service, the forgings undergo overall heat treatment (quenching + high-temperature tempering). This process produces a uniform sorbite structure, giving the gear ring high strength and toughness (typical yield strength ≥ 650 MPa), enabling it to withstand alternating bending stress and impact loads.

For applications with higher wear requirements, the tooth surface of the ring spur gear or gear ring can be further enhanced through surface hardening, carburizing, or nitriding. This improves surface hardness (typically HRC 50–60) and significantly enhances resistance to wear, pitting, and scuffing. Strict metallurgical quality control ensures that ultrasonic testing results meet standards such as JB/T 5000.15 or ASTM A388, making the ring gear reliable for long-term industrial operation.

Applications of Large Ring Gear and Ring Spur Gear in Heavy Industry

As a core transmission element, the large ring gear is widely used in heavy industrial equipment where stable torque transmission is essential.

Typical application fields include:

Metallurgical and mining industry: Ring gears for ball mills, slag drying kilns, and oxidation pellet rotary kilns

Chemical industry: Gear rings for large rotary dryers handling chemical raw materials

Environmental protection and energy industry: Large ring gears for waste incineration rotary kilns and lignite upgrading equipment

Other heavy equipment: Rotary support and drive systems in port machinery and certain wind power applications

In these scenarios, the reliability of the gear ring and the fatigue resistance of the ring gear material are critical to minimizing downtime and maintenance costs.

Types of Ring Gear: External Gear Ring and Inner Ring Gear Designs

External Gear Ring, Inner Ring Gear, and Structural Variants

According to structural design and manufacturing process, ring gears can be classified into several types:

By tooth profile and structure:

External gear ring

Inner ring gear

End face gear ring

Gear ring with flange or collar

By delivery condition:

Rough machined ring gear forgings: Forged and rough-turned with machining allowance reserved

Semi-finished or finished gear rings: Tooth profile partially or fully machined, ready for installation or final grinding

Different ring gear configurations are selected based on equipment layout, load distribution, and installation requirements.

Why Choose TIPTOP as Your Large Ring Gear and Gear Ring Manufacturer

Professional Focus and Extensive Experience

TIPTOP specializes in the manufacturing of large ring gears, gear rings, and other heavy cylindrical forgings. We have a deep understanding of application conditions, failure mechanisms, and technical requirements for large ring gear service in heavy-duty equipment. Our long-term export experience has allowed us to build a solid database of practical solutions for complex operating conditions.

Reliable Quality Assurance System

We operate under an ISO 9001-certified quality management system and can comply with standards such as API, ASTM, DIN, and GB according to customer requirements. Full-process traceability is implemented from raw material inspection and forging to heat treatment, machining, and final inspection. Each ring gear forging is delivered with complete quality documentation, including UT and heat treatment records.

Comprehensive Customer Service and Technical Support

TIPTOP provides customized large ring gear solutions based on customer drawings and operating conditions. We support various delivery forms, including complete gear rings, segmented ring gears, rough machined forgings, or fully finished products. Our engineering team assists with ring gear material selection, structural optimization, and manufacturability evaluation, helping customers reduce risk and improve equipment reliability.

Inquiry & Custom Ring Gear Solutions

If you are looking for a reliable large ring gear manufacturer with strong forging capability and strict quality control, TIPTOP is ready to support your project.

Please feel free to contact us with your drawings, technical requirements, or application details. Our engineering team will provide professional recommendations on ring gear material selection, manufacturing route, and delivery solution, ensuring your gear ring meets performance, safety, and service life expectations.

Reviews

There are no reviews yet.