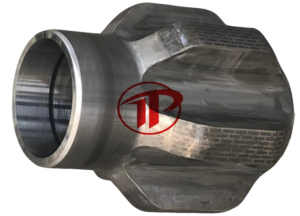

Description

The Magnadur 501 Non-Magnetic Drill Collar (NMDC) is a premium downhole drilling tool designed for demanding oil and gas operations. magnetic permeability of much less than 1.01. Its foremost function is to furnish a non-magnetic surroundings for Measurement-While-Drilling (MWD) and Logging-While-Drilling (LWD) tools, making sure particular directional measurements whilst handing over foremost mechanical support.

Technical Specifications

| Tool Joint | OD in |

Bore d in |

Length ft |

Bevel Diameter in±1/64 in |

BSR |

| NC23-31 | 3 1/8 | 1 1/4 | 30 | 3 | 2.57:1 |

| NC26-35 | 3 1/2 | 1 1/2 | 30 | 3 17/64 | 2.42:1 |

| NC35-41 | 4 1/8 | 2 | 30 or 31 | 3 61/64 | 2.43:1 |

| NC35-47 | 4 3/4 | 2 | 30 or 31 | 4 33/64 | 2.58:1 |

| NC38-50 | 5 | 2 1/4 | 30 or 31 | 4 49/64 | 2.38:1 |

| NC44-60 | 6 | 2 1/4 | 30 or 31 | 5 11/16 | 2.49:1 |

| NC44-60 | 6 | 2 13/16 | 30 or 31 | 5 11/16 | 2.84:1 |

| NC44-62 | 6 1/4 | 2 1/4 | 30 or 31 | 5 7/8 | 2.91:1 |

| NC46-62 | 6 1/4 | 2 13/16 | 30 or 31 | 5 29/32 | 2.63:1 |

| NC46-65 | 6 1/2 | 2 1/4 | 30 or 31 | 6 3/32 | 2.76:1 |

| NC46-65 | 6 1/2 | 2 13/16 | 30 or 31 | 6 3/32 | 3.05:1 |

| NC46-67 | 6 3/4 | 2 1/4 | 30 or 31 | 6 9/32 | 3.18:1 |

| NC50-70 | 7 | 2 1/4 | 30 or 31 | 6 31/64 | 2.54:1 |

| NC50-70 | 7 | 2 13/16 | 30 or 31 | 6 31/64 | 2.27:1 |

| NC50-72 | 7 1/4 | 2 13/16 | 30 or 31 | 6 43/64 | 3.12:1 |

| NC56-77 | 7 3/4 | 2 13/16 | 30 or 31 | 7 19/64 | 2.70:1 |

| NC56-80 | 8 | 2 13/16 | 30 or 31 | 7 31/64 | 3.02:1 |

| 6 5/8 REG | 8 1/4 | 2 13/16 | 30 or 31 | 7 45/64 | 2.93:1 |

| NC61-90 | 9 | 2 13/16 | 30 or 31 | 8 3/8 | 3.17:1 |

| 7 5/8 REG | 9 1/2 | 3 | 30 or 31 | 8 13/16 | 2.81:1 |

| NC70-97 | 9 3/4 | 3 | 30 or 31 | 9 5/32 | 2.57:1 |

| NC70-100 | 10 | 3 | 30 or 31 | 9 11/32 | 2.81:1 |

| 8 5/8 REG | 11 | 3 | 30 or 31 | 10 1/2 | 2.84:1 |

Key Functions and Benefits

1. Isolation from Magnetic Field Interference

MWD/LWD structures depend on Earth’s magnetic area for directional data, inclusive of nicely inclination and azimuth. Standard steel drill collars generate strong magnetic fields, disrupting measurement accuracy. The Magnadur 501 NMDC is set up above MWD/LWD equipment to act as an “isolation section,” making sure sensors function in a low-magnetic environment.

2. Rigid Support for Drilling

With excessive density and mechanical strength, the drill collar provides the essential weight on bit (WOB) and continues a secure wellbore trajectory throughout deep drilling operations.

3. Protection for Precision Instruments

Its strong shape shields touchy MWD/LWD electronics from drilling shock, vibration, and intense downhole conditions, making sure dependable overall performance over prolonged runs.

Material Properties – Magnadur 501 Alloy

Chemical Composition (%)

| Element | Min (%) | Max (%) |

| C | 0.04 | — |

| Si | 0.30 | 0.60 |

| Mn | 0.25 | 0.35 |

| P | — | 0.020 |

| S | — | 0.005 |

| Cr | 18.5 | 22.0 |

| Ni | 13.0 | 15.0 |

| Mo | 0.40 | 0.50 |

| N | 0.32 | 0.50 |

Special Characteristics

- Non-magnetic alloy with µ < 1.01

- High corrosion resistance with PREN 19 – 23

- Resistant to intergranular corrosion (ASTM A262 Practice A & E)

- Good resistance to stress corrosion cracking (SCC) with surface

- treatments like shot peening

- Suitable pitting resistance for popular drill collar use

Physical Properties

- Density: 7.8 kg/dm³ (0.282 lb/in³)

- Young’s Modulus: 195 GPa (28.3 x 10³ ksi)

- Thermal Conductivity: 14.0 W/(m·K)

- Thermal Expansion Coefficient:

20–100 °C: 16.5 × 10⁻⁶ K⁻¹

20–200 °C: 17.6 × 10⁻⁶ K⁻¹

20–300 °C: 18.5 × 10⁻⁶ K⁻¹

- Specific Heat Capacity: 0.50 kJ/(kg·K)

Quality Assurance

Each Magnadur 501 Non-Magnetic Drill Collar is manufactured below strict satisfactory manage procedures, making sure compliance with enterprise requirements and consumer specifications. Rigorous ultrasonic testing, dimensional inspections, and magnetic permeability verification assurance regular overall performance in imperative drilling environments.

Why Choose Magnadur 501 NMDC?

- Accurate MWD/LWD readings with near-zero magnetic interference

- Extended carrier existence in corrosive and high-stress downhole environments

- Proven reliability beneath intense drilling vibration and pressure

- Custom manufacturing to meet particular operational necessities

Reviews

There are no reviews yet.