Description

What Are Ring Forgings?

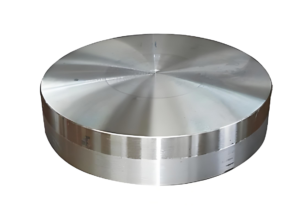

Ring forgings are indispensable components in heavy machinery and critical pressure-bearing equipment. They are formed through a forging process involving radial expansion and circumferential compression, resulting in a dense internal structure with a circumferentially distributed grain structure, and exhibiting excellent overall strength and fatigue resistance.

As a professional ring forging manufacturer, we produce custom forged rings with stable dimensions, high strength, and excellent reliability for demanding industrial use.

Applications of Forged Rings Across Industries

Our forged rings find extensive application in industries where high safety and reliability are paramount, owing to their superior mechanical performance and dimensional stability.

1. Petrochemical Ring Forgings

Forgings have wide applications in petrochemical equipment. Typical products include:

Manholes and flanges for spherical storage tanks

High-pressure welding flanges

Tube sheets and sealing rings

All of these components are finished as ring forgings requiring high toughness and corrosion resistance.

2. Nuclear Power Ring Forgings

The main large forgings in nuclear power plants are pressure vessel forgings, including:

Cylinder flanges

Nozzle sections and nozzles

Upper and lower cylinders

Cylinder transition sections

Large nuclear-grade bolts

These nuclear ring forgings must withstand extreme pressure cycles and radiation conditions.

3. Thermal Power Ring Forgings

Thermal power generation equipment contains four key forgings:

Turbine generator rotor

Retaining rings

Turbine impeller

Turbine rotor

These forged rings ensure stable high-speed rotation and resistance to thermal stress.

4. Hydropower Ring Forgings

Important forgings in hydropower stations include:

Turbine main shaft

Generator main shaft

Mirror plates

Thrust heads

These rotors and shafts require reliable large diameter ring forgings.

5. Marine Ring Forgings

Marine forgings are divided into three main categories:

Main engine forgings

Shafting forgings

Rudder system forgings

Shafting forgings include thrust shafts, intermediate shafts, and stern shafts, while rudder components include rudder stock, rudder post, and rudder pin. These parts operate in seawater and require high corrosion resistance and fatigue strength.

Key Advantages of Our Ring Forgings

1. Exceptional Mechanical Performance

Superior manufacturing processes ensure a continuous distribution of metal fiber flow lines along the circumference, resulting in forged rings with:

Outstanding circumferential strength

High toughness and fatigue resistance

Excellent stress corrosion resistance

Performance is far superior to welded or cast products.

2. High Reliability and Safety

The highly dense and uniform internal structure, with minimal segregation and porosity defects, allows forged rings to withstand enormous static and dynamic impacts. This makes them particularly suitable as critical pressure-bearing components in demanding environments.

3. Large-Diameter & Heavy-Duty Customization

Equipped with ultra-large rolling mills and heat treatment furnaces, we can meet requirements for:

Ultra-large diameter forged rings

Ultra-thick-walled ring forgings

Custom shapes and special steels

We regularly supply custom forged rings up to several meters in diameter for heavy industrial use.

Material Options for Forged Rings

We offer a variety of high-quality alloy steels and special materials tailored to different application environments (high temperature, high pressure, corrosion, heavy load), ensuring forged rings meet stringent operational demands:

High-strength alloy steels:

42CrMo4, 34CrNiMo6 (EN 10250-3, ASTM A668)

Used for wind turbine bearings and heavy machinery slewing rings.

Pressure vessel steels:

ASME SA-508 / SA-105

Used for nuclear and petrochemical pressure components, flanges, and tube sheets.

Stainless steels:

ASTM A182 F316 / F316L

Ideal for marine sealing rings and chemical environments.

Tool & bearing steels:

GCr15

Used for rolling bearing inner/outer rings and wheel hoops.

All materials are traceable with full MTC certificates available.

Inspection Standards & Quality Assurance

Our ring forgings strictly adhere to international quality systems and inspection standards:

Standards

API

ASME B16.5 / B16.47

EN 10250

ASTM A668

Non-Destructive Testing (NDT)

All forged rings undergo 100% inspection:

Ultrasonic Testing (UT):

According to ASTM A388 / EN 10228

Ensures no internal defects such as shrinkage cavities or inclusions.

Magnetic Particle / Penetrant Testing (MT/PT):

Detects surface microcracks.

Mechanical Properties Example (S135 Steel Grade)

Tensile strength: >1034 MPa

Yield strength: >931 MPa

Your Trusted Ring Forgings Supplier

With decades of forging experience, advanced equipment, and strict testing systems, we supply high-performance large ring forgings for industries such as:

Petrochemical

Nuclear & thermal power

Hydropower

Marine & shipbuilding

Heavy machinery

We support custom designs, rapid delivery, third-party inspection, and export packaging.

Contact Us for Custom Forged Rings

If you are looking for a reliable ring forging supplier, we can provide engineered solutions according to your drawings and technical requirements.

📌 Custom sizes available

📌 Small to extra-large diameters

📌 OEM / ODM service welcomed

Reviews

There are no reviews yet.