Description

The sleeve’s function is to provide mechanical stability to the drill string while ensuring the accuracy of directional measurement data by creating a non-magnetic environment for Measurement While Drilling (MWD) and Logging While Drilling (LWD) tools.

1. Core Function of the Non-magnetic Sleeve: Achieving Precise Directional Measurement

This is the most critical and unique difference between non-magnetic stabilizers and standard stabilizers.

In directional and horizontal drilling, MWD tools use triaxial magnetometers (similar to a three-dimensional compass) to determine the wellbore’s azimuth (direction) relative to the Earth’s magnetic north.

If the drill string components surrounding these sensitive sensors (including the stabilizer) are made of standard magnetic steel (e.g., carbon steel), a localized magnetic field will be generated. This magnetic field interferes with and distorts the Earth’s natural magnetic field, causing significant errors in azimuth calculations. This can cause the drill bit to deviate from the intended wellbore trajectory.

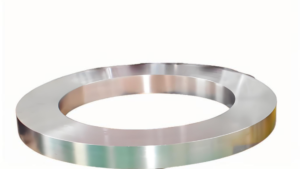

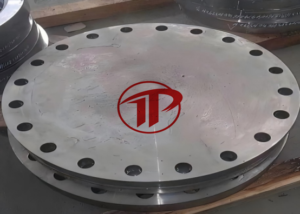

Solution: A non-magnetic stabilizing sleeve, made of a non-magnetic material (e.g., P530 or P550 non-magnetic steel), is placed directly above or near the measurement-while-drilling (MWD) tool in the bottom-of-well assembly (BHA), forming a “non-magnetic section” or “non-magnetic collar.” This sleeve shields the magnetometer from magnetic interference from the upper drill string, ensuring the reliability and accuracy of directional data.

2. Mechanical Functions: Wellbore Stabilization and Trajectory Control

As “stabilizers,” they perform all the necessary mechanical functions:

Centering the Drill String: Maintaining the drill string in a centered position within the wellbore, reducing excessive bending, vibration, and harmful contact with the wellbore wall.

Controlling the Wellbore Trajectory: By forming a defined contact point with the formation, they act as a fulcrum for the drill bit. This is crucial for executing directional changes—whether increasing or decreasing the drilling rig inclination, or maintaining a stable drilling trajectory.

Improved drilling efficiency and wellbore quality: They mitigate destructive vibrations (such as vortex and stick-slip vibrations), thereby more effectively transferring pressure to the drill bit, ultimately increasing the rate of penetration (ROP) and achieving a smoother, caliber-compliant wellbore.

Protected downhole tools: By stabilizing the drill string assembly, they reduce the shock and vibration loads on sensitive measurement-while-drilling (MWD)/log-while-drilling (LWD) tools and other downhole tool components, extending their service life.

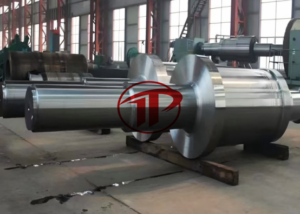

Replaceable sleeve design: They are typically designed as sleeves fitted onto a standard steel mandrel. This allows for easy field replacement of worn non-magnetic sleeves without replacing the entire expensive stabilizer assembly, resulting in significant cost savings.

Abrasion resistance: The sleeve blades or outer surface are typically hardfaced with tungsten carbide or other abrasion-resistant materials to withstand the effects of abrasive formations and maintain their stable diameter over extended operating cycles.

3. Typical Applications of Non-Magnetic Stabilizing Sleeves

Non-magnetic stabilizing sleeves are essential components in any drilling operation requiring precise directional control, including:

l Directional drilling

l Horizontal drilling

l Extra-long horizontal drilling (ERD)

l S-type and J-type wellbore profiles

l Any wellbore section measured using magnetic measurement while drilling (MWD) tools.

Looking for Reliable Non-Magnetic Stabilizer Sleeves?

If you are sourcing non-magnetic stabilizer sleeves for MWD/LWD applications, we can supply customized solutions based on your BHA design, well profile, and operating conditions. Our sleeves are manufactured from proven non-magnetic alloys with strict control over mechanical properties, magnetic permeability, and dimensional accuracy.

📩 Contact us today to discuss your technical requirements, material options, and delivery schedule—we’re ready to support your drilling operations with dependable, field-proven non-magnetic stabilizer solutions

Reviews

There are no reviews yet.