Description

Introduction to Non-Magnetic Sub Crossovers

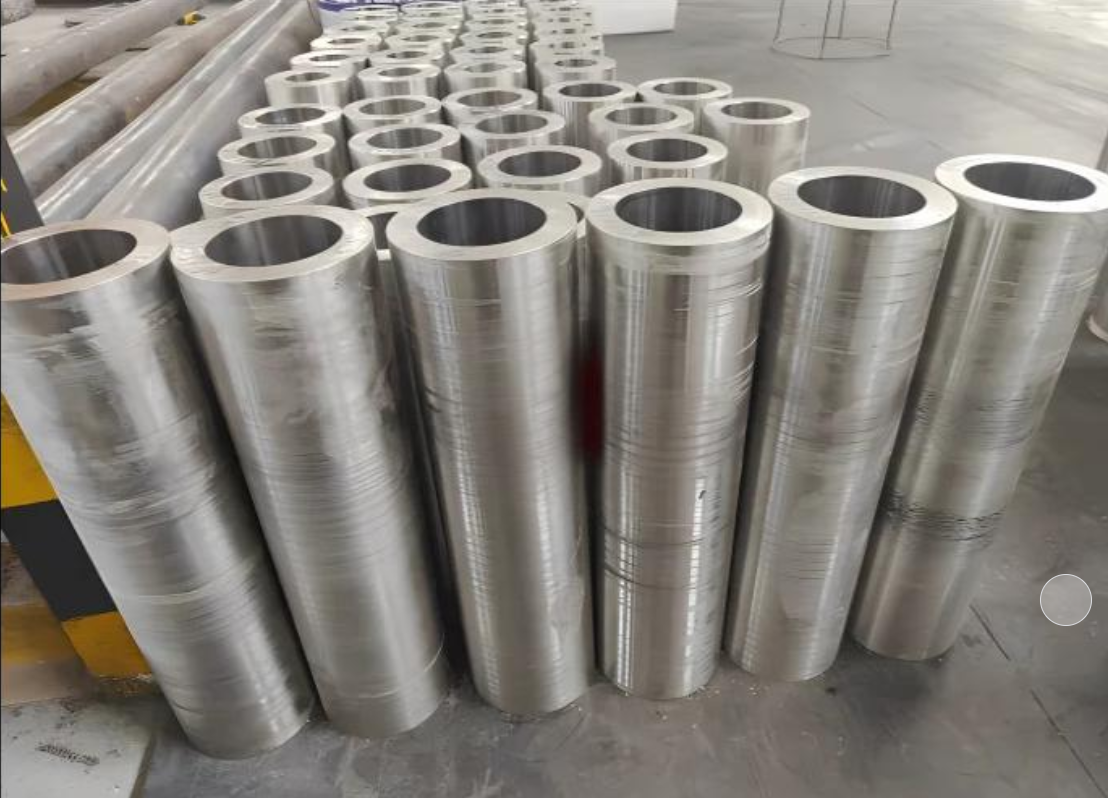

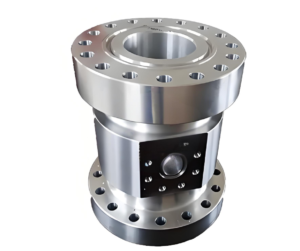

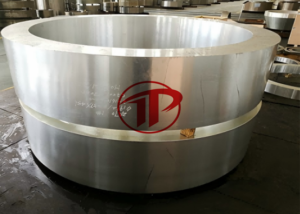

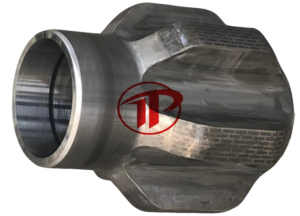

Non-Magnetic Sub Crossovers are quintessential drill string factors manufactured from tremendous non-magnetic stainless steel or nickel-based alloys. Designed to achieve absolutely uncompromised directional drilling accuracy, these submersibles preserve unbiased magnetic signatures, allowing sensitive MWD (measurement while drilling) and LWD (logging while drilling) equipment to reject magnetic interference.

Key Features & Benefits

✅ Magnetically Transparent – Crafted from pinnacle category non-magnetic resources to prevent any distortion of surrounding magnetic fields.

✅ Exceptional Corrosion Resistance – Superior overall performance in harsh downhole environments with publicity to H₂S, CO₂, and different corrosive agents.

✅ Precision Thread Connections – Designed and machined to API and top rate connections for seamless integration with drill strings and bottom-hole assemblies.

✅ High Fatigue Strength – Built to undergo excessive torsional and axial masses in directional and horizontal drilling operations.

✅ Tight Dimensional Control – CNC-machined for best suit and excessive repeatability, making sure lengthy carrier existence and handy dealing with in the field.

Typical Applications

Directional and horizontal drilling

Logging-while-drilling (LWD) and measurement-while-drilling (MWD) toolstrings

High-performance rotary steerable systems

Deepwater and harsh surroundings wellbores

Extended attain drilling (ERD) projects

Material Grades and Specifications

Material Typical Properties

P530/P550 (Non-Mag Stainless Steel) Very low magnetic permeability, excessive power and toughness

Nickel-Based Alloy Enhanced corrosion resistance, suitable for high-pressure and high-temperature wells

Why Choose Our Non-Magnetic Sub Crossovers?

Our non-magnetic sub crossovers are engineered for precision, durability, and compliance with API standards. Our superior manufacturing techniques and rigorous exceptional checking out make sure each section meets or exceeds OEM tolerances. Whether you’re working in offshore deepwater wells or onshore directional programs, our non-magnetic subs will assist defend your equipment and optimize performance.

Customization & Support

We provide customized sizes, connections, and lengths tailor-made to your genuine properly design. Our skilled engineering crew is accessible to seek advice from on fabric selection, thread types, and fatigue-critical diagram for most effective performance.

Contact us these days to request a quote or get technical help from our specialists.

Reviews

There are no reviews yet.