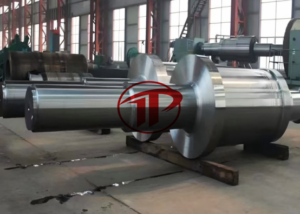

Description

Non-magnetic drill collar a critical downhole tool designed to ensure measurement accuracy and operational reliability in oil and gas drilling. This model is engineered from special non-magnetic, austenitic Mn-Cr-Mo-N steel with exceptional corrosion resistance, specifically developed for harsh oilfield environments.

Purpose and Key Benefits

P650 NMDC to serve as an isolation section between the drill string and sensitive MWD/LWD tools. By eliminating magnetic field interference, it enables precise directional measurements for well inclination and azimuth. At the same time, it delivers the rigidity and weight required to stabilize the wellbore trajectory while physically protecting internal electronic instruments from vibration and shock.

Technical Specifications

| Tool Joint | OD in |

Bore d in |

Length ft |

Bevel Diameter in±1/64 in |

BSR |

| NC23-31 | 3 1/8 | 1 1/4 | 30 | 3 | 2.57:1 |

| NC26-35 | 3 1/2 | 1 1/2 | 30 | 3 17/64 | 2.42:1 |

| NC35-41 | 4 1/8 | 2 | 30 or 31 | 3 61/64 | 2.43:1 |

| NC35-47 | 4 3/4 | 2 | 30 or 31 | 4 33/64 | 2.58:1 |

| NC38-50 | 5 | 2 1/4 | 30 or 31 | 4 49/64 | 2.38:1 |

| NC44-60 | 6 | 2 1/4 | 30 or 31 | 5 11/16 | 2.49:1 |

| NC44-60 | 6 | 2 13/16 | 30 or 31 | 5 11/16 | 2.84:1 |

| NC44-62 | 6 1/4 | 2 1/4 | 30 or 31 | 5 7/8 | 2.91:1 |

| NC46-62 | 6 1/4 | 2 13/16 | 30 or 31 | 5 29/32 | 2.63:1 |

| NC46-65 | 6 1/2 | 2 1/4 | 30 or 31 | 6 3/32 | 2.76:1 |

| NC46-65 | 6 1/2 | 2 13/16 | 30 or 31 | 6 3/32 | 3.05:1 |

| NC46-67 | 6 3/4 | 2 1/4 | 30 or 31 | 6 9/32 | 3.18:1 |

| NC50-70 | 7 | 2 1/4 | 30 or 31 | 6 31/64 | 2.54:1 |

| NC50-70 | 7 | 2 13/16 | 30 or 31 | 6 31/64 | 2.27:1 |

| NC50-72 | 7 1/4 | 2 13/16 | 30 or 31 | 6 43/64 | 3.12:1 |

| NC56-77 | 7 3/4 | 2 13/16 | 30 or 31 | 7 19/64 | 2.70:1 |

| NC56-80 | 8 | 2 13/16 | 30 or 31 | 7 31/64 | 3.02:1 |

| 6 5/8 REG | 8 1/4 | 2 13/16 | 30 or 31 | 7 45/64 | 2.93:1 |

| NC61-90 | 9 | 2 13/16 | 30 or 31 | 8 3/8 | 3.17:1 |

| 7 5/8 REG | 9 1/2 | 3 | 30 or 31 | 8 13/16 | 2.81:1 |

| NC70-97 | 9 3/4 | 3 | 30 or 31 | 9 5/32 | 2.57:1 |

| NC70-100 | 10 | 3 | 30 or 31 | 9 11/32 | 2.81:1 |

| 8 5/8 REG | 11 | 3 | 30 or 31 | 10 1/2 | 2.84:1 |

Material Excellence – Chemical Composition

P650″ is a special nonmagnetic, austenitic Mn-Cr-Mo-N-steel with a high pitting corrosion resistance, specifically developed for oilfield applications.

| C | Mn | Cr | Mo | Ni | N |

| Max.0,06 | 19,50-20,50 | 18,00-19,00 | 1,70-2,00 | 3,00-4,50 | 0,55-0,65 |

Mechanical Strength and Performance

Following mechanical properties (tested at room temperature) are achieved by a special cold-working process over the full length of the collar:

| Yield Strength (min.):

0,2%-offset method |

OD up to 9 1/4″ | 140 ksi | 965 N/mm² |

| OD 91/2″ and larger | 130 ksi | 900 N/mm² | |

| Tensile Strength (min.): | 150 ksi | 1035 N/mm² | |

| Elongation (min.): | 20% | 20% | |

| Reduction of area (min.): | 50% | 50% | |

| Impact energy (min.): | 60 ft.lb | 82 J | |

| Endurance Strength /N=107(min.): | 60 ksi | 414 N/mm² | |

| Hardness Brinell: | 330-430 HB | 330-430 HB | |

Corrosion & Magnetic Integrity

P650 apply special surface treatments such as hammer peening, roller burnishing, and shot peening to prevent transgranular SCC. Intergranular SCC is avoided through quenching after warm forging. Each collar undergoes 100% magnetic inspection with a Förster Magnetomat 1.782 “Hot Spot” test and is ultrasonically inspected to ASTM E 114 standards, guaranteeing full compliance with international quality requirements.

Why Choose My P650 Non-Magnetic Drill Collar

High Precision: Minimizes magnetic interference for accurate MWD/LWD readings.

Robust Strength: Maintains borehole stability and transmits optimal drilling weight.

Exceptional Durability: Withstands harsh environments and extends operational lifespan.

Proven Quality: Every collar is tested, certified, and backed by my manufacturing expertise.

If you need a reliable, high-strength, and corrosion-resistant NMDC for demanding oilfield drilling operations, P650 Non-Magnetic Drill Collar offers the perfect balance of performance and durability

Reviews

There are no reviews yet.