Titanium alloys are the first materials that come to mind when talking about an outstanding strength-to-weight ratio, corrosion resistance, and high-temperature performance. As the use of these materials keeps expanding in the aerospace, oil & gas, marine, and chemical industries, it is becoming more and more essential that buyers and engineers comprehend titanium alloy materials, their composition, forms, and the processes by which they are made.

Being an experienced titanium alloys supplier and a titanium forgings manufacturer company, TIP TOP Forging is capable of providing the whole range of titanium alloy products – from the raw materials to the precision-forged and machined components, to the worldwide industrial applications with a stable quality and reliable delivery.

Titanium Alloys Meaning: What Is in Titanium Alloy Materials

Titanium alloy meaning defines metallic materials whose major constituent is titanium, to which small quantities of alloying elements are added such as aluminum, vanadium, molybdenum, nickel, or iron for property modification and enhancement.

So, what is in titanium alloy exactly?

A typical titanium alloy composition includes:

Titanium

Alpha stabilizers (Al, O)

Beta stabilizers (V, Mo, Nb, Fe)

These combinations result in different titanium alloy products, each designed to deliver maximum strength, resistance to corrosion, good welding ability, or heat tolerance.

Titanium Alloy Composition and Titanium Alloys Classification

Titanium alloys can be categorized based on their microstructure into:

Alpha Titanium Alloys

Excellent corrosion resistance and thermal stability, suitable for chemical and marine environments.

Alpha-Beta Titanium Alloys

The most widely used titanium alloy materials, balancing strength and toughness. TC4 / GR5 is a typical example.

Beta Titanium Alloys

High strength and formability, used in advanced aerospace and structural applications.

Commonly used steel grades internationally include:

Pure Titanium: TA1 / GR1, TA2 / GR2, TA3 / GR3, TA4 / GR4

Titanium Alloys: TC4 / GR5, TA9 / GR7, TA10 / GR12, TC11, TA15, TA18 / GR9, TC18, TC20, TC21

Titanium Alloys Aerospace Applications and Titanium Alloy Percentage in Aerospace

Titanium alloys aerospace usage continues to increase due to weight reduction and structural efficiency.

In modern aircraft and engines, the percentage of titanium in an alloy used in aerospace structures typically ranges from 6% to over 15% of total airframe weight, and even higher in aero-engine components.

Common titanium alloys aerospace applications include:

Aircraft structural frames

Engine compressor discs and blades

Landing gear components

Aerospace titanium alloy rings and forgings

Forging Titanium Alloys: From Billet to High-Performance Components

Forging titanium alloys significantly improves grain structure, fatigue resistance, and mechanical consistency compared to cast or rolled products.

TIP TOP Forging specializes in:

Titanium alloy rings and titanium alloy ring forgings

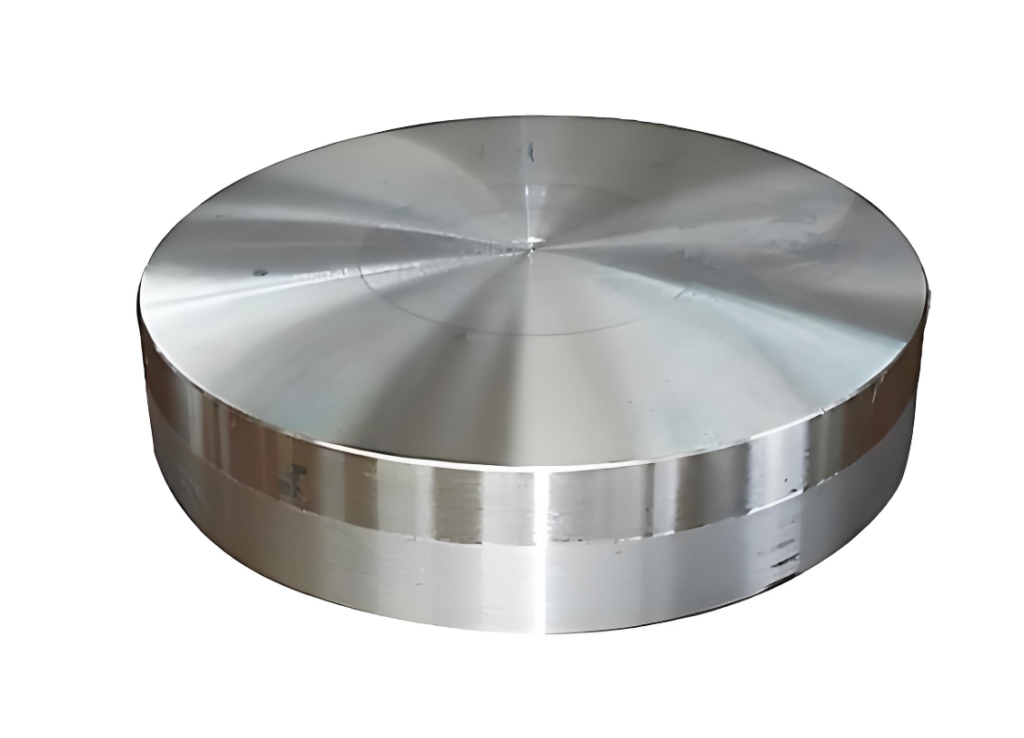

Titanium alloy forged discs and blocks

Titanium alloy flanges and custom-shaped forgings

Our forging process ensures controlled deformation and strict heat treatment, meeting aerospace, oilfield, and industrial standards.

Titanium Alloy Bar, Sheet and Ring Products for Industrial Use

To meet diverse application needs, we supply multiple product forms:

Titanium alloy bar (round, square, forged or rolled)

Titanium alloy sheet and titanium alloy sheets for forming and fabrication

Titanium alloy rings for pressure vessels and rotating equipment

These titanium alloy materials are widely used in energy equipment, marine systems, chemical processing, and structural assemblies.

Titanium Alloys for Oil & Gas and Special Equipment Applications

TIP TOP Forging provides titanium alloys specifically engineered for harsh environments, including:

Titanium alloy non-magnetic drill rods and bars

Titanium alloy oil exploration probes

Titanium alloy impellers and connectors

We also manufacture:

Titanium alloy rotors and protective sleeves

Titanium alloy pressure-resistant cabins

Titanium alloy and nickel-based alloy shafts

Deep Processing and Customized Forging Titanium Alloys

Beyond raw materials, we offer full-process manufacturing:

Precision-machined titanium alloy components

Custom-shaped forged parts

Titanium alloy fasteners: bolts, nuts, washers, pins

Our production integrates forging, heat treatment, machining, and inspection—ensuring consistency from billet to finished part.

Titanium Alloy Price Factors and Cost Considerations

The price of titanium alloy and titanium alloy price depend on several factors:

Alloy grade and composition

Product form (bar, sheet, ring, forging)

Forging ratio and processing complexity

Certification and inspection requirements

As a direct manufacturer, TIP TOP Forging helps customers optimize cost without compromising material integrity or performance.

Why Choose TIP TOP Forging as Your Titanium Alloys Supplier

As an experienced titanium alloy supplier, TIP TOP Forging offers:

Complete titanium alloy materials and forged products

Stable supply of aerospace and industrial grades

Custom forging titanium alloys based on drawings

Only top quality control and confirmation to international standards

We will deliver dependable solutions that match your application, even if you require titanium alloy bars, sheets, rings, or completely machined parts.

Get in touch with TIP TOP Forging for Titanium Alloys Solutions

When you are looking for top-quality titanium alloys, forged rings, bars, sheets, or tailor-made titanium alloy components, TIP TOP Forging is at your service to assist with your project.

Drop us a line with your drawings or specifications, and our technical team will be at your disposal to give you professional recommendations on materials and competitive prices.