Introduction to Closed Die Forging

Closed Die Forging vs. Open Die Forging

Unlike open die forging, the place metal is deformed freely between flat dies, closed die forging restricts cloth waft the usage of fashioned cavities. This effects in tighter tolerances, greater repeatability, and the potential to produce extra complicated geometries.

Why Closed Die Forging Is Widely Used

Thanks to its capability to produce consistent, strong, and complicated parts, closed die forging is the favored preference in industries such as aerospace, automotive, strength generation, and heavy machinery.

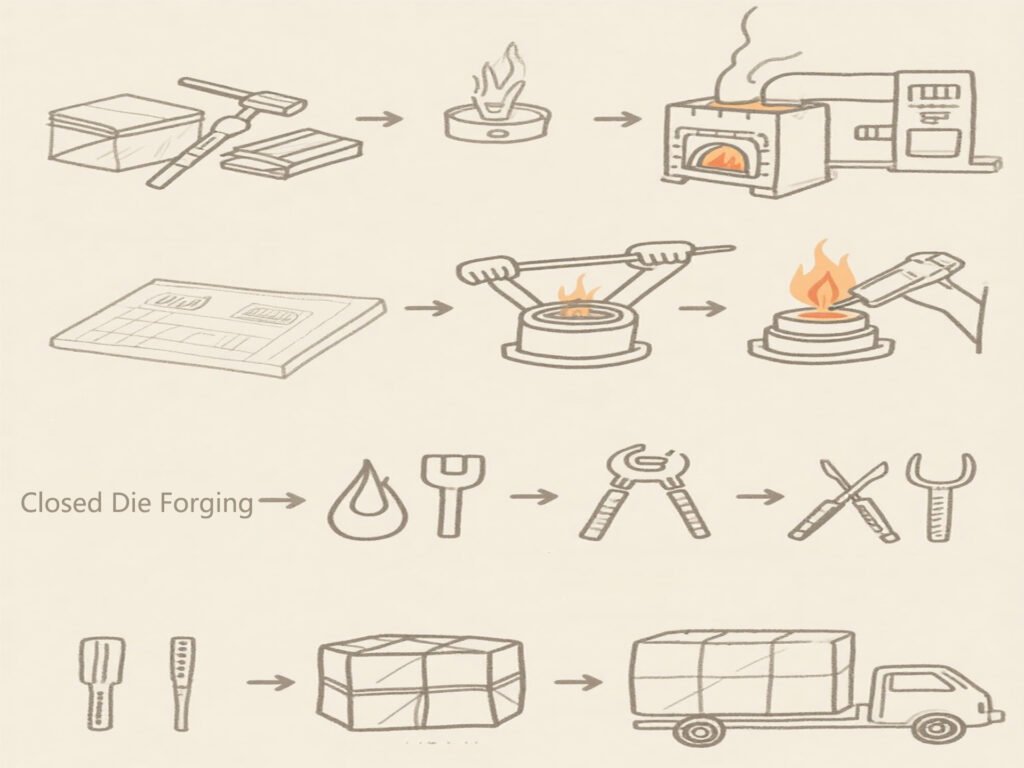

Closed Die Forging Process Steps

1️⃣ Material Selection and Preparation

Suitable forging materials (e.g., carbon steel, alloy steel, aluminum) are selected based on mechanical and thermal requirements. Raw stock is cut and prepped for forging.

2️⃣ Heating the Workpiece

The billet is uniformly heated to forging temperatures—typically 1,100°C to 1,250°C for steel—to ensure formability without degrading its integrity.

3️⃣ Placement into the Die

The heated billet is carefully placed in the lower die cavity, ensuring correct alignment for accurate forming.

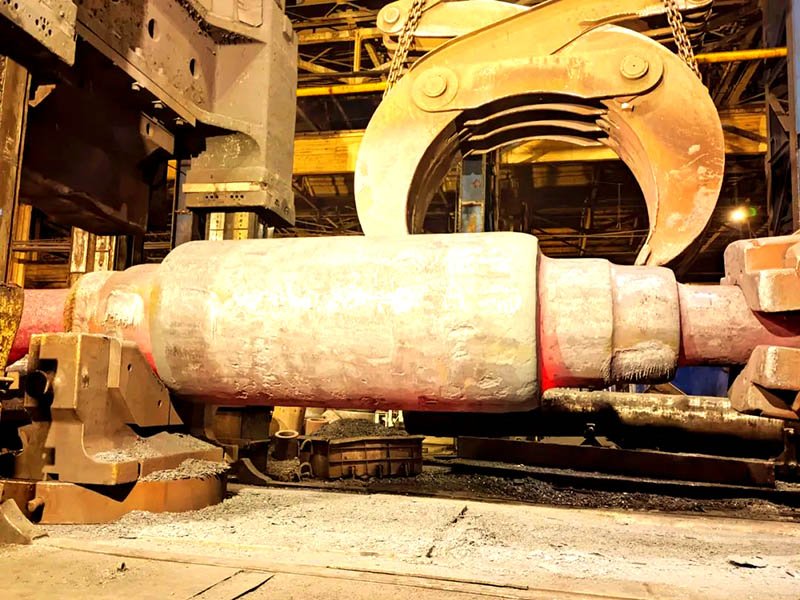

4️⃣ High-Pressure Forming

A forging press or hammer applies high force, pushing the metal into the die cavity to form the final shape with precision.

5️⃣ Trimming, Heat Treatment, and Final Processing

Excess flash is removed, and the part may undergo further processing like heat treatment or surface finishing for enhanced performance.

Common Equipment Used

Typical equipment includes mechanical and hydraulic presses, screw presses, induction heaters, trimming machines, and automated handling systems.

Key Advantages of Closed Die Forging

Superior Dimensional Precision

High consistency and precision often eliminate or reduce the need for secondary machining.

Exceptional Mechanical Properties

Directional grain flow and refined structure lead to better strength, ductility, and fatigue resistance.

Material Savings

Near-net shaping significantly reduces material waste—especially valuable when working with high-cost alloys.

High Production Efficiency

Once dies are ready, the process is fast, repeatable, and ideal for medium to high-volume production.

Design Flexibility for Complex Parts

Supports the forging of intricate shapes with added features like ribs, bosses, and fillets directly in the die.

Typical Applications of Closed Die Forging

Automotive Components

Gears, crankshafts, steering knuckles, and connecting rods—all requiring high strength and tight tolerances.

Aerospace Structures

Ideal for landing gear, turbine disks, and engine components that require fatigue resistance under extreme conditions.

Agricultural and Construction Machinery

Heavy-duty components like brackets, couplers, and shafts for off-road, high-impact environments.

Oil, Gas, and Power Generation

Forged components such as flanges, valve bodies, and pressure housings that must withstand high stress and temperatures.

Related Products

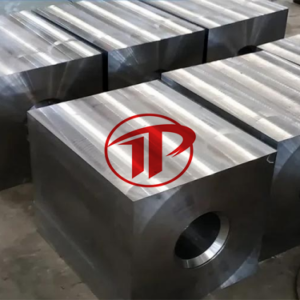

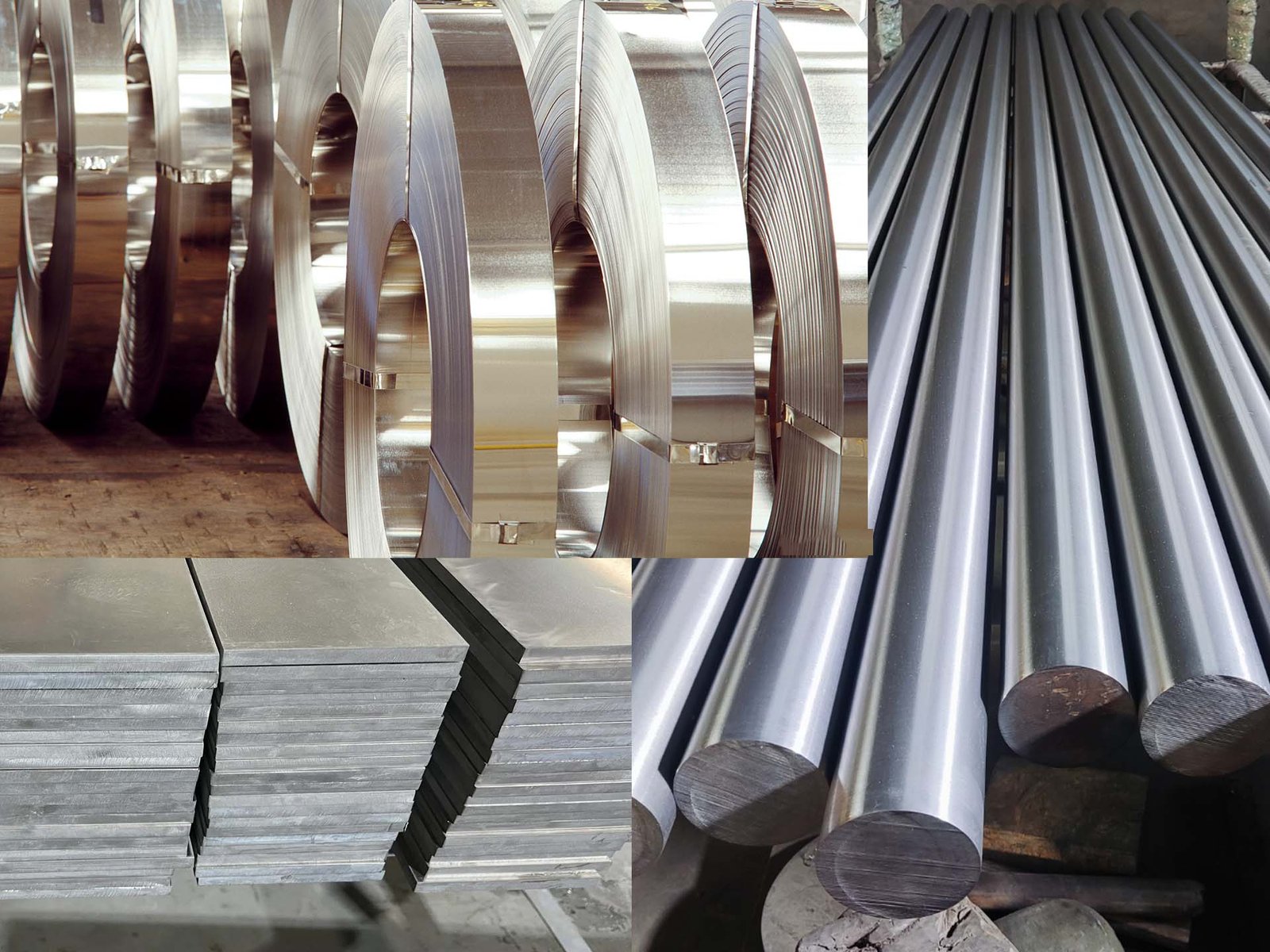

Materials Used in Closed Die Forging

Carbon Steel

Cost-effective and suitable for general-use components requiring good strength and machinability.

Alloy Steel

Offers enhanced hardness, wear resistance, and strength—ideal for demanding applications.

Aluminum and Copper Alloys

Lightweight, corrosion-resistant options commonly used in aerospace, automotive, and electrical systems.

Stainless Steel and High-Temperature Alloys

Used in high-corrosion or high-heat environments such as medical, aerospace, and energy industries.

Closed Die Forging vs. Other Manufacturing Methods

Closed Die Forging vs. Open Die Forging

Closed die forging delivers better accuracy and finish, while open die forging suits larger, simpler shapes with lower production volumes.

Closed Die Forging vs. Casting/Machining

Forging yields denser, stronger parts than casting and creates less material waste than machining.

When to Choose Closed Die Forging

Best for high-strength, high-precision, and safety-critical parts in medium to large production runs.

Conclusion and Final Takeaways

Summary of Benefits

Closed die forging combines strength, accuracy, material efficiency, and design flexibility into one robust manufacturing solution.

Is It Right for Your Project?

Ideal for applications that demand structural integrity, fatigue resistance, and dimensional precision.

Call to Action

Need a custom forging solution? Contact our team today for expert consultation and a competitive quote.