In stressful industrial purposes — from aerospace engines to deep-sea drilling gear — the strength, reliability, and customizability of factors are critical. Open die forging, with its unmatched mechanical houses and bendy manufacturing capabilities, has end up the go-to answer for top-performing industries. This article explores the key motives why open die forging has earned tremendous have faith amongst main sectors.

Introduction to Open Die Forging

What is Open Die Forging?

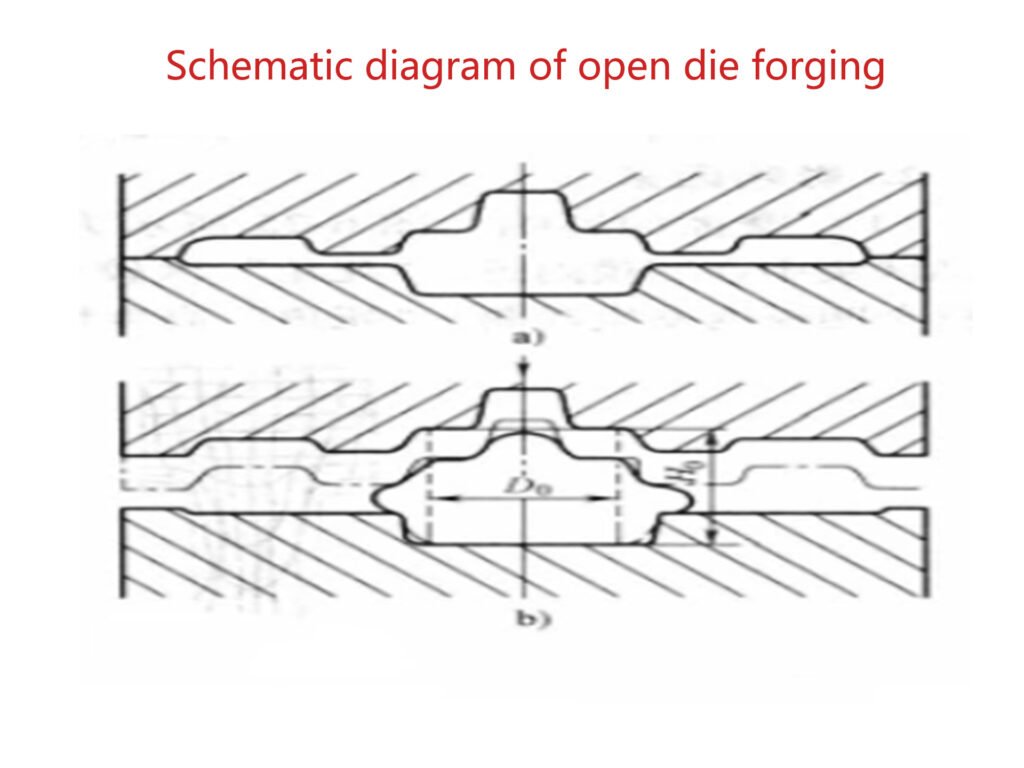

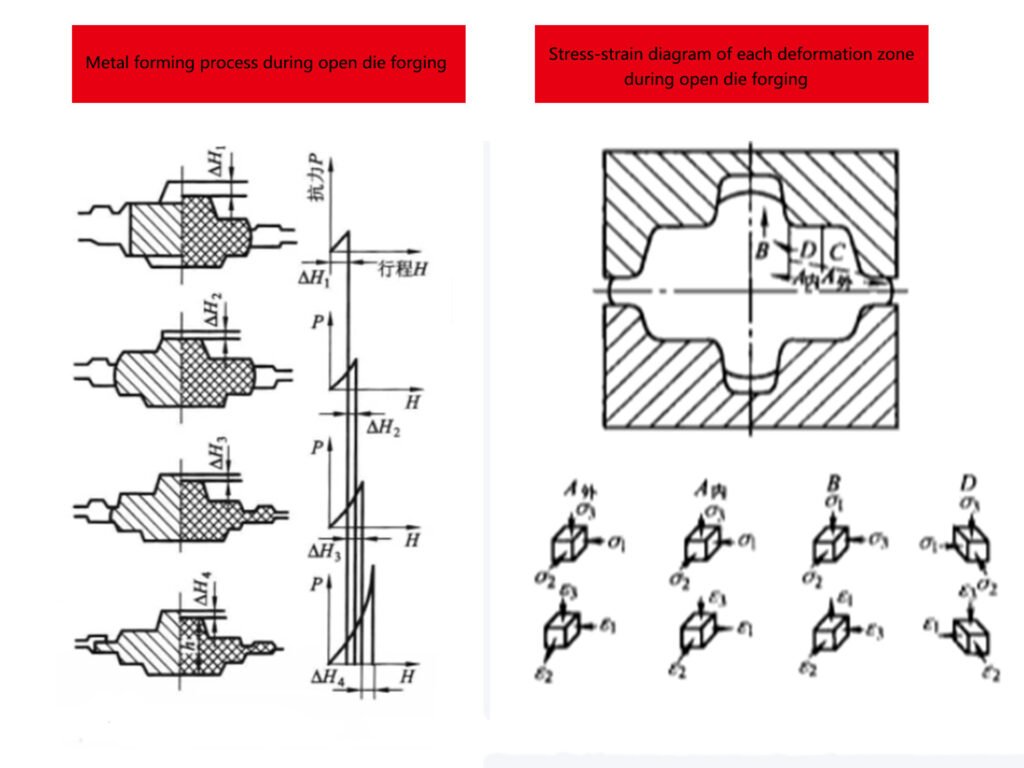

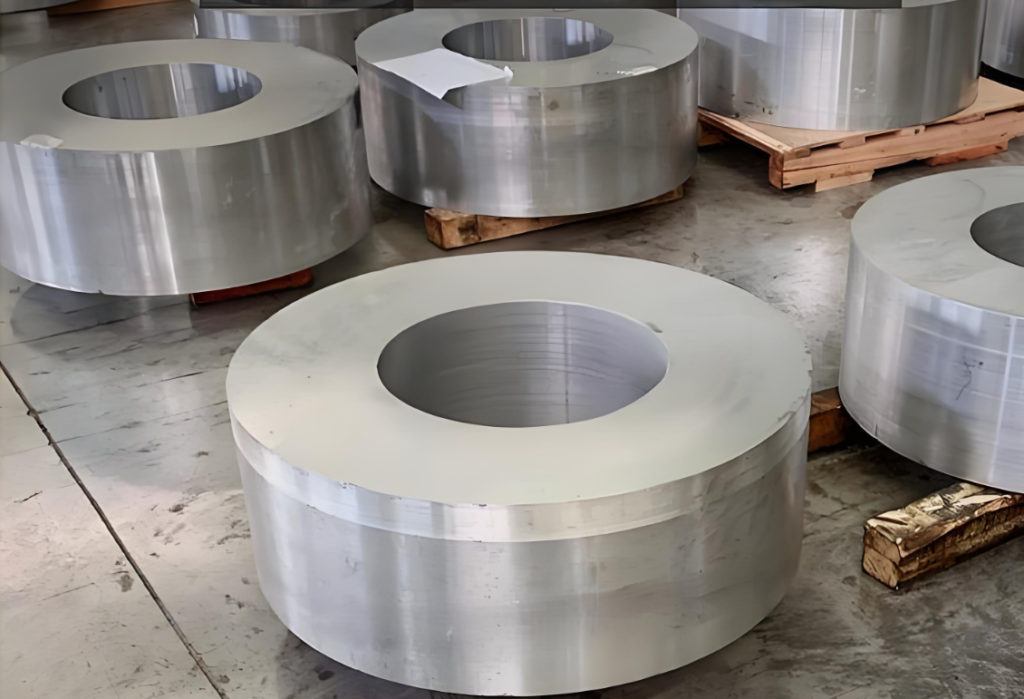

Open die forging, also known as free forging, is a metal shaping process in which the material is repeatedly compressed between flat or contoured dies, without full enclosure. The material flows freely, allowing operators to precisely control the shape and dimensions of large and complex components.

How It Differs from Closed Die Forging

Unlike closed die forging — which uses fixed molds to shape metal — open die forging offers:

No need for expensive dies, saving upfront costs

Ideal for large, low-quantity, or custom-shaped parts

Better material flow and microstructural control

Growing Demand Across Industries

As industries push for stronger, customized components capable of withstanding extreme environments, demand for open die forging continues to rise.

Key Advantages of Open Die Forging

Improved Mechanical Properties

Open die forging eliminates internal voids and aligns grain flow with part geometry, significantly improving:

Tensile strength

Fatigue resistance

Impact toughness

Superior Grain Structure and Strength

By controlling temperature and deformation path, open die forging creates a fine and uniform grain structure, critical for high-load, high-performance parts.

Flexibility for Large and Complex Shapes

Open die forging is well-suited for:

Irregular or custom-shaped components

Reduced Material Waste and Cost Efficiency

Compared to casting and closed die forging, this process offers higher material utilization — especially valuable for expensive alloys — thus improving cost efficiency.

Better Control Over Final Product Quality

The gradual shaping process allows for better in-process monitoring and quality assurance, ideal for safety-critical parts.

Industries That Rely on Open Die Forging

Aerospace – High-Performance Components

Aerospace demands lightweight yet ultra-strong parts like landing gear and engine rotors. Open die forging ensures exceptional strength and structural integrity.

Oil & Gas – Pressure-Resistant Parts

Subsea wellheads, drill collars, and stabilizers operate under extreme pressure and corrosion. These parts require dense, defect-free forgings.

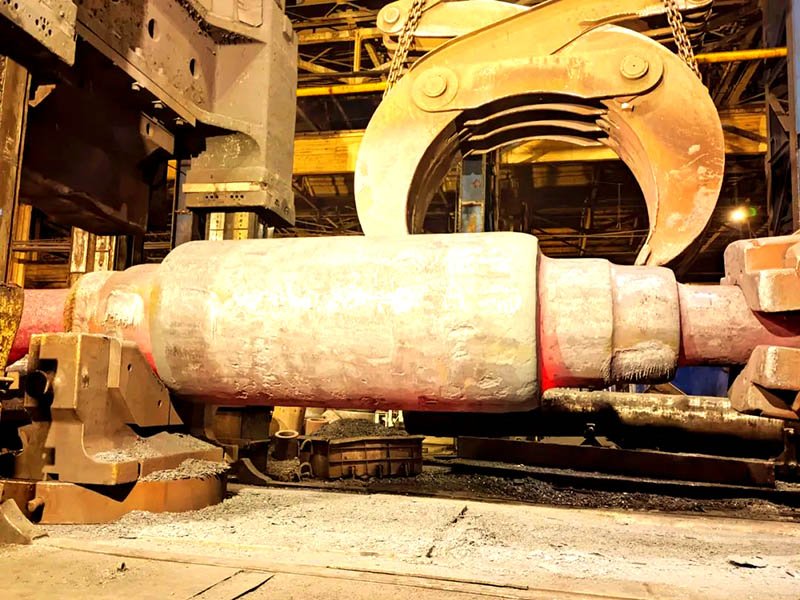

Power Generation – Turbine Shafts and Rotors

From nuclear to hydro and gas plants, large forged rotors, shafts, and disks are essential for safe and reliable power generation.

Heavy Equipment & Mining – Structural Components

Earthmovers, crushers, and haulers use large support arms, shafts, and frames. Forgings ensure durability and long service life under dynamic loads.

Marine & Offshore – Propulsion Systems

Open die forgings are used in ship propeller shafts, rudders, and offshore platform structures, offering corrosion resistance and longevity in harsh environments.

Why Leading Industries Prefer Open Die Forging

Customization for Unique Requirements

Open die forging allows for adjustments in:

Length-to-diameter ratios

Wall thickness or hollow sections

Alloy composition and heat treatment

This flexibility is best for bespoke industrial needs.

Durability and Reliability in Critical Applications

Forged components characteristic optimized grain orientation, satisfactory microstructure, and managed density — making sure they outperform solid or fabricated alternatives.

Outstanding Performance in Harsh Environments

Whether uncovered to excessive pressure, severe temperatures, or corrosive media, forgings persistently supply top-tier reliability.

How to Choose the Right Open Die Forging Partner

Certifications and Quality Standards (ISO, AS9100, etc.)

Reputable partners comply with industry-leading standards, offering:

Traceable production

Certified material testing

Documented quality assurance

Proven Expertise and Capabilities

Evaluate if the supplier can handle:

Exotic materials like Inconel or titanium

Large or irregular dimensions

Complex forging and heat treatment

Commitment to Precision and On-Time Delivery

Advanced machinery, automated processes, and responsive project management ensure tight tolerances and reliable timelines.

Conclusion and Key Takeaways

Why Open Die Forging Remains a Trusted Choice

Open die forging delivers unmatched strength, flexibility, and quality — making it the solution of choice in aerospace, energy, marine, and heavy industries.

Final Advice for Selecting the Right Forging Partner

When sourcing an open die forging partner, prioritize:

Global certifications

Custom engineering capabilities

On-time, high-precision delivery

Proven industry track record

Frequently Asked Questions (FAQ)

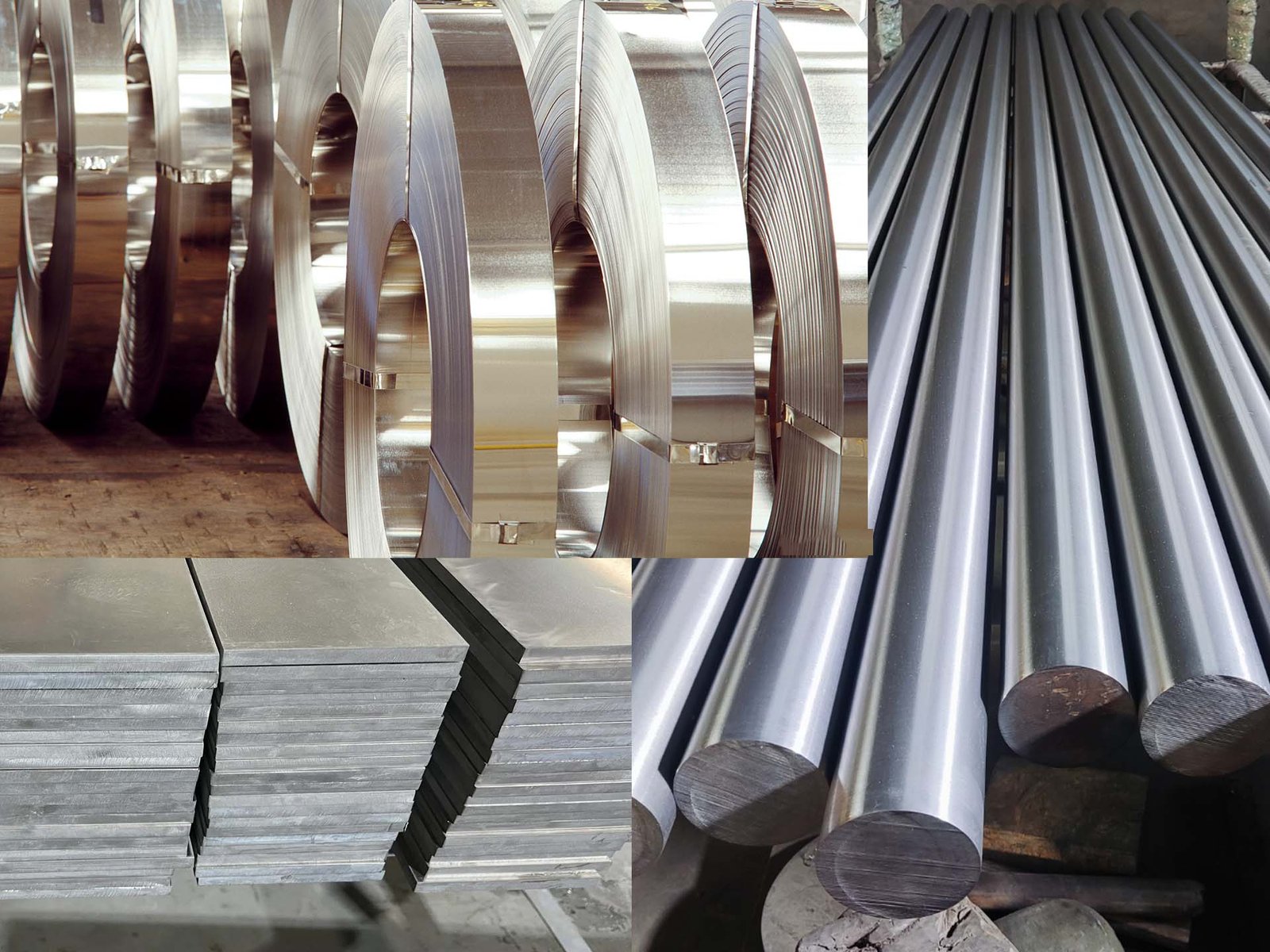

What Materials Are Best for Open Die Forging?

Materials often solid consist of carbon steel, alloy steel, stainless steel, titanium, and nickel-based alloys like Inconel — chosen based totally on overall performance requirements.

How Does Open Die Forging Improve Mechanical Properties?

The technique re-aligns the interior grain float and eliminates voids, bettering strength, ductility, and fatigue resistance.

Is Open Die Forging Cost-Effective for Low Volume?

Yes. Since it doesn’t require devoted dies, open die forging is perfect for one-off, prototype, or low-quantity production, imparting each fee and time advantages.