Introduction: Why Choose Customized Forged Components?

In today’s disturbing industrial landscape, off-the-shelf components frequently fall brief when performance, durability, and protection depend most. That’s the place custom-made solid options come in.

Forging is already recognized for producing stronger, extra dependable components than casting or fabrication. But customization takes it a step in addition — giving you exactly the dimensions, materials, mechanical properties, and shapes your utility demands.

✅ Reduce downtime with perfect-fit parts

✅ Enhance protection and reliability in crucial systems

✅ Lower lifetime fees via higher durability

What Does “Customized Forged” Mean?

“Customized forged” refers to steel aspects produced via forging strategies however tailor-made in particular to your requirements.

Instead of regular inventory parts, you get forgings designed to meet your exact:

Dimensions and tolerances

Material grades

Mechanical properties

Surface finishes

Heat remedy specifications

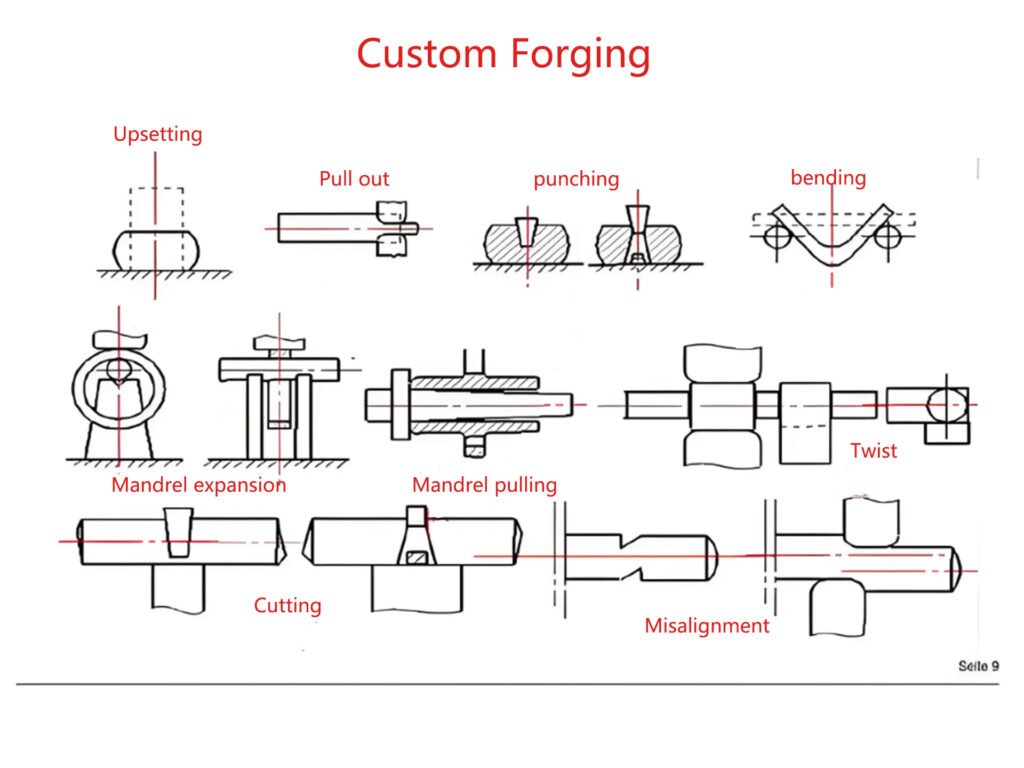

Forging approaches used can include:

✅ Open die forging — perfect for large, low-volume parts

✅ Closed die forging — for complex, repeatable shapes

✅ Rolled ring forging — for seamless rings in necessary applications

Advantages of Customized Forged Components

✅ Superior Strength and Toughness

Forging aligns grain waft with the part’s shape, minimizing vulnerable points. This leads to:

High influence resistance

Excellent fatigue life

Reliability below shock loads

✅ Material Versatility

Choose precisely what you need:

Titanium and more

Each cloth can be optimized for corrosion resistance, temperature stability, or weight savings.

✅ Tailored Mechanical Properties

Through specific warmness cure and managed forging, you get the actual hardness, ductility, and sturdiness your layout demands.

✅ Cost-Effective for Complex Shapes

Custom forging reduces machining waste and eliminates welding or meeting of more than one parts, reducing expenses and simplifying designs.

Typical Industries and Applications

Customized solid solutions are used anyplace failure is no longer an option:

Wellhead equipment

Valve bodies

Subsea connectors

Flanges

Alloy Steel Forged Bar Supplier – Built for Oil & Gas Performance

With superior mechanical strength, excellent impact resistance, and exceptional fatigue life, forged bars outperform conventional rolled or cast materials in harsh drilling, extraction, and processing environments.

Turbine shafts

Pressure vessel components

Wind tower flanges

Dual-flange Spacer Spool Forging

A dual-flange spacer spool is a key fitting used to connect two pipelines, pipe fittings, or components.

Engine components

Landing equipment parts

Structural rings

Aerospace Spacecraft Interior Components

Aerospace interior components refer to various parts used inside spacecraft.

Gears and shafts

Crusher components

Bearing housings

✅ Marine and Shipbuilding

Propeller shafts

Coupling rings

Mooring components

✅ Construction and Industrial Machinery

Hydraulic cylinder parts

Crane components

Track links

How Does the Custom Forging Process Work?

1️⃣ Design and Engineering

Your wishes are translated into specified engineering drawings and forging simulations to make certain feasibility.

2️⃣ Material Selection

Premium uncooked substances are sourced to meet requirements like ASTM, ASME, EN, and API.

3️⃣ Forging

Open die, closed die, or rolled ring forging strategies structure the phase whilst refining grain flow.

4️⃣ Heat Treatment

Processes such as normalizing, quenching and tempering, or annealing attain centered mechanical properties.

5️⃣ Machining and Finishing

CNC machining ensures unique dimensions. Surfaces can be polished, coated, or included as needed.

6️⃣ Inspection and Certification

Ultrasonic trying out (UT), magnetic particle inspection (MPI), and dimensional exams make certain compliance with your specs.

Why Choose Us for Your Customized Forged Needs?

✅ Expertise in Diverse Forging Methods

We produce open die, closed die, and rolled ring forgings — some thing fits your phase best.

✅ Wide Material Capability

From carbon steels to superior alloys, our sourcing and checking out make sure quality.

✅ Full-Service Manufacturing

We take care of forging, warmth treatment, machining, testing, and international delivery.

✅ Certified Quality Management

Our manufacturing is backed through ISO 9001 and industry certifications. Full traceability and inspection reviews come standard.

✅ Global Supply Capability

We supply on time worldwide, with impervious packaging and transport solutions.

FAQs About Customized Forged Solutions

✅ What substances can you forge?

Carbon steels, alloy steels, stainless steels, nickel-based alloys, titanium alloys, and greater — matched to your environment.

✅ What sizes can you produce?

From small precision components beneath 1 kg to giant open-die aspects weighing numerous tons.

✅ Do you furnish warmness cure and machining?

Yes — in-house warmness cure and precision CNC machining for ready-to-install parts.

✅ Can you grant certifications?

All deliveries can encompass EN 10204 3.1 / 3.2 certificates, UT/MPI reports, and third-party inspections as required.

Conclusion: Invest in Quality with Customized Forged Solutions

Customized forged components supply unmatched strength, durability, and reliability for the hardest industrial applications.

Whether you’re in oil & gas, strength generation, aerospace, mining, or marine industries, deciding on tailor-made forged components means:

✅ Higher protection margins

✅ Fewer screw ups and downtime

✅ Lower complete fee of ownership