Forging quality is critical for high-performance applications

The Link Between Forging Quality and Product Reliability

In high-performance environments, the smallest defect can lead to catastrophic failure. Forging amazing ensures that elements show off the mechanical strength, fatigue resistance, and dimensional integrity required to meet immoderate average overall performance demands.

Common Failures Caused by way of Poor Forging Quality

Subpar forging practices can end result in:

Internal voids and porosity

Inconsistent grain flow

Cracks or floor defects

Imprecise position and size

These defects affect the safety, performance and service life of the closure product.

Industry where high performance cannot be compromisedForging first-rate is specially imperative in:

Aerospace – turbine disks, touchdown gear, structural components

Energy – energy era shafts, turbine rotors

Automotive – high-stress crankshafts, suspension arms

Oil & Gas – drill collars, valves, and high-pressure components

Key Factors That Determine Forging Quality

Material Selection and Grade Integrity

Using the proper alloy and licensed grade is the basis of high-performance forging. The fabric need to offer the required strength, warmness resistance, and fatigue lifestyles for its end-use application.

Precision in Die Design and Tooling

Accurate die geometry and custom tooling contribute to:

Consistent part dimensions

Proper grain flow orientation

Minimized post-forging machining

Controlled Heating and Forging Temperatures

Precise thermal management prevents:

Grain growth

Uneven deformation

Cracking during processing

A regular heating technique is indispensable for retaining metallurgical integrity.

Strict Quality Control and Testing Standards

High-quality forging involves:

Non-destructive trying out (UT, MPI, X-ray)

Mechanical property verification (tensile, impact, hardness)

Dimensional inspection the use of CMM or laser scanning

Consistent Dimensional Accuracy

Tight tolerances and consistency are fundamental for components that must:

Integrate seamlessly with assemblies

Withstand dynamic or cyclical loads

Function in high-pressure or high-temperature environments

How High-Quality Forging Enhances Performance

Improved Fatigue Resistance

Grain refinement, suited fiber alignment, and void-free buildings extensively make bigger the fatigue lifestyles of cast parts.

Better Grain Flow and Strength

Forging forces steel grains to float alongside the contours of the part, bettering tensile and yield strength, specifically in fundamental load paths.

Greater Impact Toughness

High-quality forgings can take in shock hundreds barring cracking, making them appropriate for dynamic or safety-critical functions.

Superior Corrosion and Wear Resistance

Proper forging practices can enhance:

Surface finish

Material density

Resistance to pitting, erosion, and wear

This is by and large valuable in harsh environments such as marine, mining, or chemical processing.

The Role of a Skilled Forging Partner

Engineering Expertise in Material and Process Selection

An skilled forging company will:

Recommend most appropriate metal or alloy grades

Select appropriate forging strategies (open-die, closed-die, rolled ring)

Advise on warmth cure and machining needs

Proven Processes and Industry Certifications (ISO, AS9100, etc.)

Look for partners with:

Documented quality systems

Certifications relevant to your industry

A track record of audit compliance and traceability

Customized Solutions for High-Demand Applications

High-performance applications require:

Design consultation

Tailored forging parameters

Integrated testing and certification services

Real-World Examples of Performance-Driven Forging

Aerospace Case Study – Aircraft Engine Components

Precision-forged turbine disks and shafts must:

Withstand high thermal stress

Maintain balance at extreme RPMs

Survive fatigue over long service lives

Automotive Example – High-Performance Crankshafts

Forged crankshafts deliver:

Improved fatigue strength

Better vibration resistance

Reliable power transmission under racing conditions

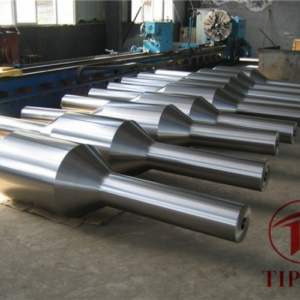

Energy Industry – Turbine Shafts and Power Generation Parts

In power plants, forged rotors and generator shafts must:

Operate 24/7 at extreme temperatures and pressures

Offer zero defect tolerance

Pass rigorous ultrasonic and hardness tests

Conclusion and Key Takeaways

Recap: Why Forging Quality Matters

High-performance applications depend on:

Material integrity

Precision tooling

Consistent quality control

These factors directly impact safety, performance, and reliability

Call to Action: Partner With Experts to Unlock Maximum Performance

Choose a forging partner with:

Proven engineering capability

High standards of quality assurance

Experience in your industry’s most demanding requirements

Frequently Asked Questions (FAQ)

How Is Forging Quality Measured?

Key metrics include:

Grain structure analysis

Mechanical property testing

Non-destructive examination

Tolerances and dimensional checks

What Tests Validate the Mechanical Properties of a Forged Part?

Common tests include:

Tensile strength

Charpy impact

Rockwell or Brinell hardness

Microstructure analysis after etching

Can Forging Quality Be Improved After Production?

To a limited extent, yes:

Heat treatment can enhance mechanical properties

Surface finishing can improve wear resistance