Introduction to Forging

What Is Forging?

Forging is a metalworking procedure the place compressive forces are utilized to structure metallic into preferred forms. It improves mechanical strength, refines grain structure, and eliminates interior defects — making it one of the most dependable manufacturing methods.

A Brief History of Forging in Manufacturing

From historical blacksmiths hammering equipment to today’s high-precision industrial presses, forging has advanced into a extraordinarily advanced, engineered process. It performs a crucial position in aerospace, automotive, energy, and heavy equipment sectors.

Why It’s Important to Understand Different Forging Types

Choosing the proper forging kind impacts cost, durability, performance, and manufacturing feasibility. Understanding the 5 most important sorts helps engineers, buyers, and undertaking managers make knowledgeable sourcing decisions.

5 Main Types of Forging Explained

(A direct and user-expected list format)

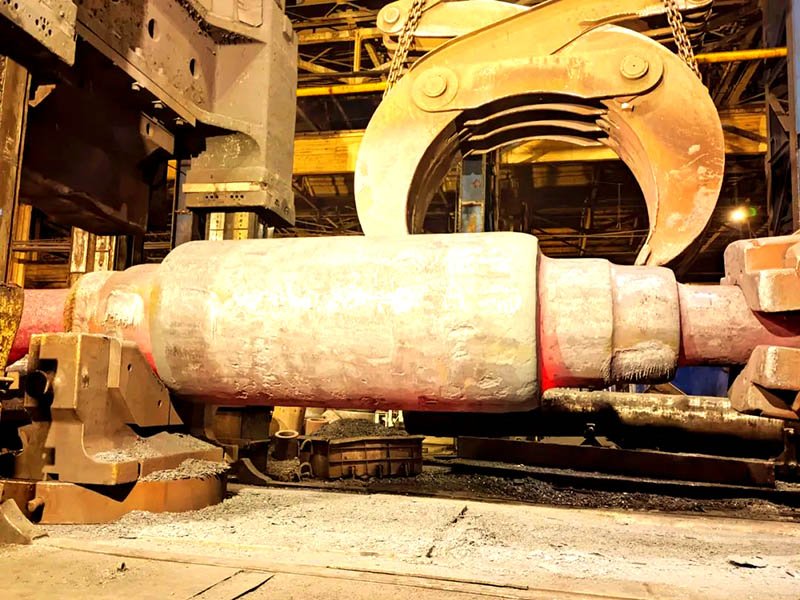

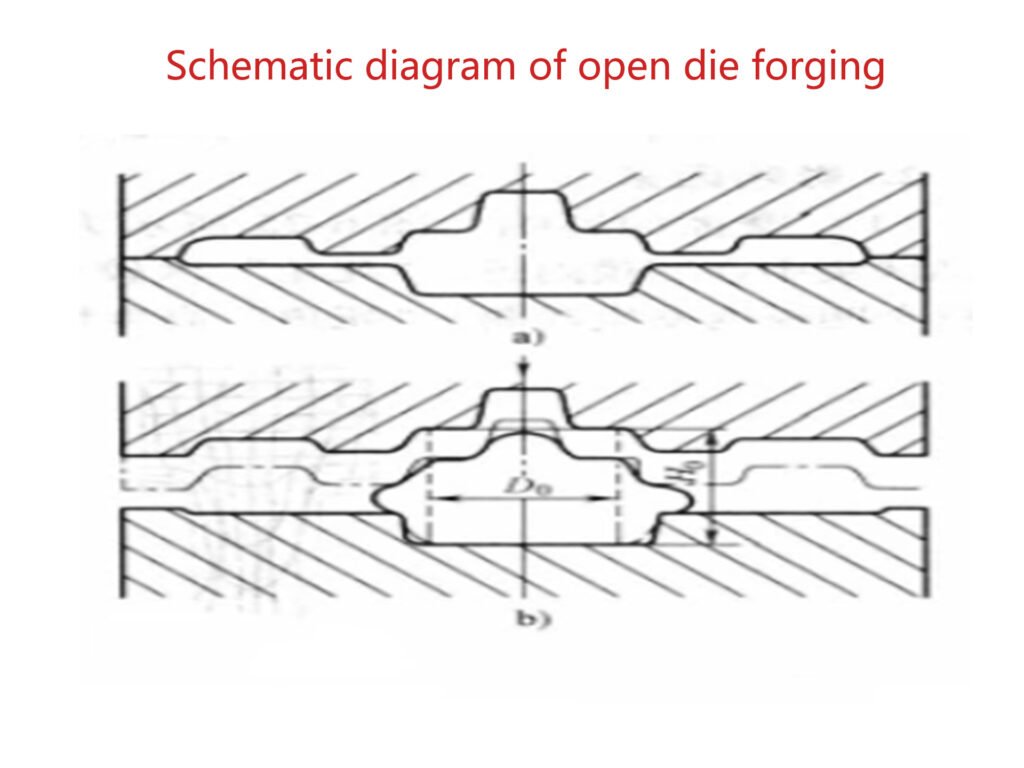

1. Open Die Forging

What It Is:

Open die forging involves shaping metal between flat or contoured dies that do not enclose the material entirely. Operators manually control the shaping process.

Key Advantages:

Excellent grain structure and mechanical properties

Ideal for large, simple or custom parts

No expensive tooling required

Common Applications:

Shafts, rings, blocks, and bars in aerospace, oil & gas, and heavy machinery

2. Closed Die Forging (Impression Die Forging)

What It Is:

Metal is compressed within a die cavity that completely contains the material, producing near-net shapes.

Advantages for Complex Shapes:

High precision and repeatability

Greater production speed

Less post-machining required

Industries Where It Excels:

Automotive components, hand tools, connectors, valves

3. Seamless Rolled Ring Forging

How It Works:

A pierced cylindrical blank is rolled under extreme pressure into a ring shape. The diameter can range from a few inches to several meters.

Strength & Size Benefits:

Superior radial and axial strength

Excellent for handling rotational stress

Material efficiency for large rings

Typical Applications:

Bearings, flanges, gear rings, turbine rings in aerospace and energy sectors

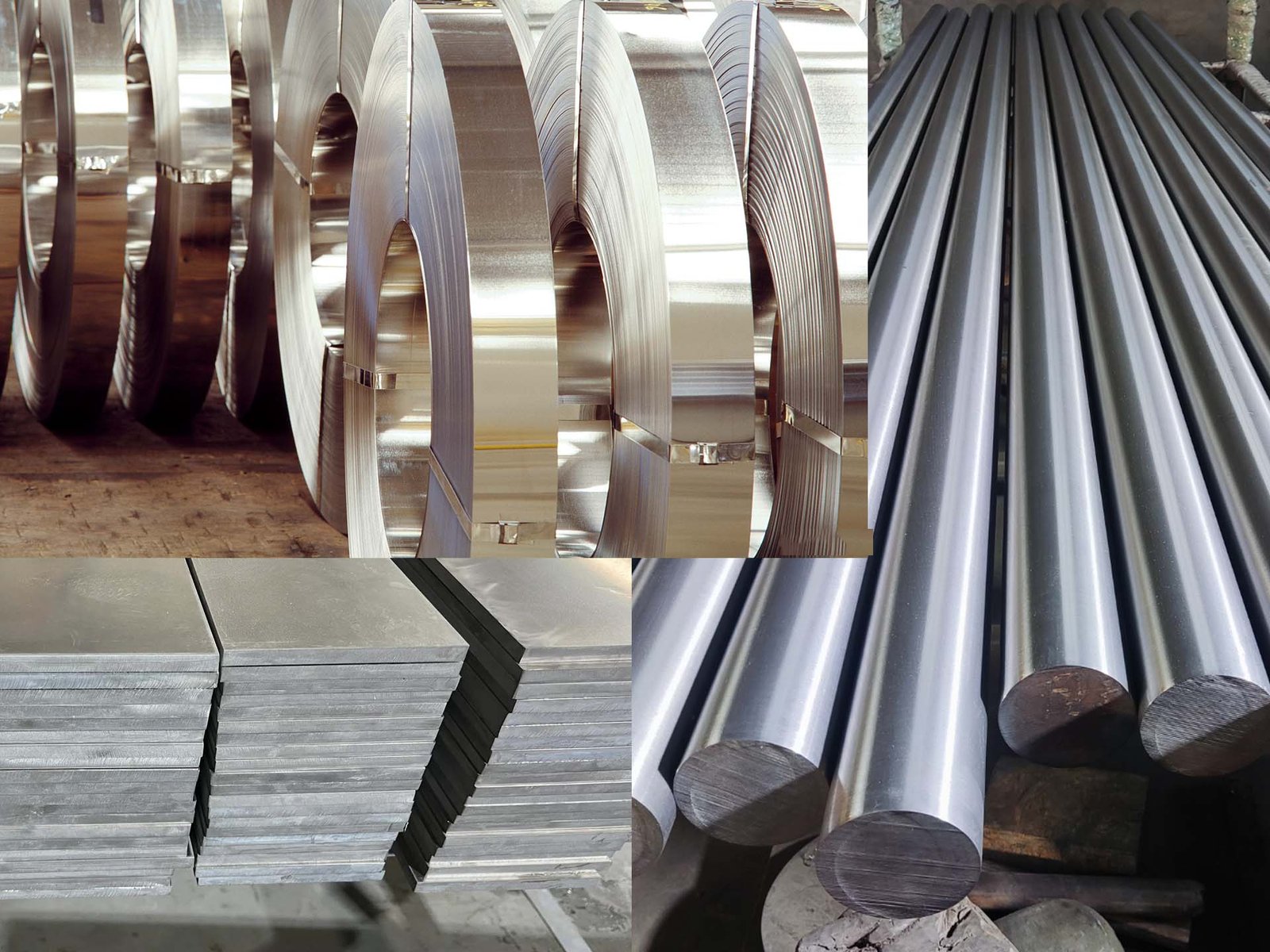

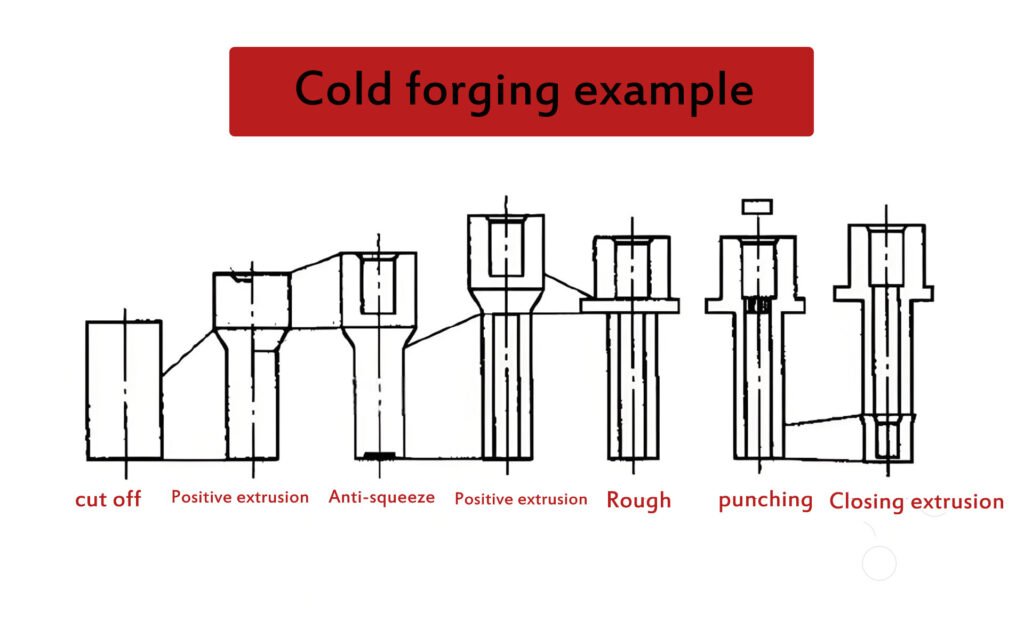

4. Cold Forging

Deformed at Room Temperature:

Cold forging shapes metal without heating, relying on high pressure.

Advantages in Accuracy & Surface Finish:

Tight dimensional tolerances

Excellent surface finish

Minimal material waste

Ideal Use Cases:

Fasteners, shafts, rivets, small gear parts

5. Warm Forging

Processed at Intermediate Temperatures (Between Cold and Hot Forging):

Typically carried out between 500°C and 900°C, warm forging balances the benefits of cold and hot processes.

Why Choose Warm Forging?

Reduced forming loads

Good surface quality

Better material flow than cold forging

Best Materials and Products:

Steel and aluminum parts with medium complexity

Ideal for automotive components and industrial connectors

How to Choose the Right Forging Type for Your Project

Key Factors to Consider (Material, Shape Complexity, Budget)

Selecting the best forging method depends on:

Material properties (ductility, temperature tolerance)

Part complexity (near-net shapes vs custom sizes)

Cost considerations (tooling, volume, finishing)

Balancing Performance and Cost

Open die forging may offer superior strength, but closed die forging may be more economical for high-volume parts. Match process to project priorities.

Consult with Forging Experts

An experienced forging supplier can guide you to the right solution, offering technical support, material advice, and custom options.

Summary Table: Comparing the 5 Types of Forging

| Forging Type | Temperature | Suitable Materials | Shape Complexity | Common Applications |

| Open Die Forging | Hot (1000°C+) | Steel, Nickel, Titanium | Low to Medium | Shafts, blocks, rings |

| Closed Die Forging | Hot (1000°C+) | Steel, Aluminum | High | Auto parts, tools |

| Seamless Rolled Ring | Hot (1000°C+) | Steel, Inconel | Ring-shaped, Large | Bearings, turbines, flanges |

| Cold Forging | Room Temperature | Soft steel, aluminum | Simple, High volume | Screws, bolts, shafts |

| Warm Forging | 500–900°C | Steel, Aluminum | Medium complexity | Engine parts, couplings |

Conclusion and Key Takeaways

Recap of the Five Forging Types

Each forging method offers unique benefits:

Open die for large custom parts

Closed die for high-precision shapes

Ring forging for large load-bearing rings

Cold forging for small, high-volume parts

Warm forging as a balanced middle ground

Why Understanding the Differences Matters

Choosing the incorrect method can lead to greater costs, delayed timelines, and underperforming parts. Understanding forging kinds ensures smarter sourcing and higher outcomes.

Frequently Asked Questions (FAQ)

Which Forging Type Is Best for High-Strength Components?

Open die and seamless ring forging produce the strongest components due to grain refinement and directional strength.Are Open Die and Closed Die Forging Interchangeable?

Not usually. Open die is better for large or custom shapes, while closed die excels in mass production of complex parts.

What’s the Cost Difference Between Warm and Cold Forging?

Warm forging typically requires less forming force and post-machining than cold forging, but involves higher energy use. Cold forging may be more cost-efficient for simpler, smaller parts.